-

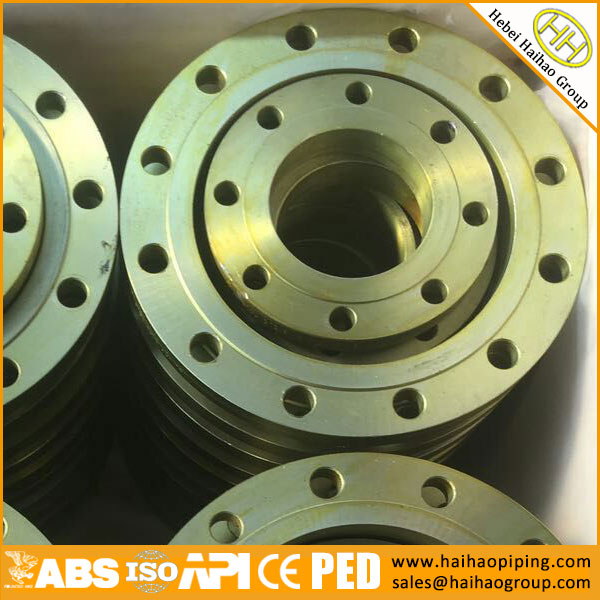

What factors affect the sealing performance of pressure vessel flanges?

The tightness of the pressure vessel flange will be affected by the bolt pretension, gasket sealing performance, flange sealing surface characteristics, flange stiffness and operating conditions during use. Let me take a closer look. 1.Bolt pre-tightening force Appropriate pre-tightening force c ...

-

Safe and efficient transportation enables you to receive the goods as soon as possible

Imagine the time and effort wasted when you sent out one inquiry after another, compared one offer after another, and finally chose a company to work with. But when you receive the goods only to find that the goods are missing, damaged, the production does not meet the expected standards, which ...

-

Order for complete flanges in Russia

The following are the order from old Russian customers in June. The general product description is for example: Set of companion flanges, gaskets, bolts and nuts, consist of: 2 x weld neck flanges ASME B16.5 (DN 3″, Pressure class: ANSI 300, material: A182 F9), 2 x Gaskets (SWG, 304SS/Grap ...

-

What is ZPS washer and HCS washer?

In the previous articles, the main product types of insulation kits are basically introduced. Finally, it is worth noting that it was mentioned in the initial introduction to the components of the insulation kit, “3. Steel Washer: ZPS Washer;” and “4. Insulating Washer: HCS Washer.” The HCS was ...

-

What is LPG gasket?

HPG gasket was introduced in the previous article, and then let’s learn about the light green LPG gasket. In fact, from the comparison of these two type pictures, we can found that the black HGP is thicker, while the light green LGP is lighter. Light green LPG gasket LPG system is an insul ...

-

What is HPG gasket?

It can be found from the product pictures in the previous article that there are two sets of insulation kits with different colors, one is black and the other is light green. In fact, there are also two types of insulation gaskets, HPG for black and LPG for light green. Now let’s introduce ...

-

What is flange insulation kit?

The flange insulation kit is used for insulation during flange connection.Generally, the flange insulation kit is composed of four parts, which of course does not include other requirements of the clients in the product description, such as bolts and nuts matching the flanges. Flange insulation ...

-

API 6A standard blind flange with three coats of paint coating order follow up

Introduction to blind flange with three coats of paint-the customer is satisfied with the additional order of the last product. I didn’t know if you had any impression on the three-layer painted API 6A 6BX blind flange we provided to customers last time. This time, we ushered in a follow-u ...

-

API 6A standard blind flange with three coats of paint coating

The formal name of blind flange is flange cover, and some are also called blind flange or pipe plug. It is a flange without a hole in the middle, which is used to block the pipe opening. The function is the same as that of the head and pipe cap, except that the blind seal is a removable sealing ...

-

For ship repairs job raw material with BV certificate

After the perfect delivery of the first order, the customer was satisfied and gave follow-up orders Similarly, according to the requirements of the shipowner, BV surveyor is required to do 3.2 test the customer ordered some fittings and flanges.Here are some product descriptions. DIN 1093-P35 ...

-

ASME B16.48 304 figure-8 flanges exported to Oman

Haihao group is committed to providing the best quality ASME B16.48 304 figure-8 flanges. 304 is a universal stainless steel, which is widely used in the manufacture of equipment and parts requiring good comprehensive properties (corrosion resistance and formability). To maintain the corrosion r ...

-

The type of the flange sealing surface

The tightness of the flange is directly related to the sealing surface of the flange-pressed gasket, and the commonly used flange sealing surface types are three as follows. Flat face type sealing surface The flat flange sealing surface is a very smooth plane with the advantages of simple struct ...