-

Big size caps welded with flanges

We got order about cement lining caps welded with flange . Order is for a water reclamation plant project the PUB is the Singapore’s national water agency public utilities water reclamation department. Cement mortar lining can better prevent hard objects and sewage and other direct wear of ...

-

Use and connection of spectacle blind

The spectacle blind is a kind of pipe part, which is mainly for the convenience of maintenance. You can paint the upper half of “8” black. It’s half a blind plate and half an iron ring. Spectacle blind flange do not have bolt holes. It is only used for isolation between two fla ...

-

Characteristics of spectacle blind

The spectacle blind is a kind of pipe part, which is mainly for the convenience of maintenance. You can paint the upper half of “8” black. It’s half a blind plate and half an iron ring. It is commonly used for pipeline flanges that need to change the process. The materials are ...

-

Hebei Haihao Group finished weld neck flange order from SNGPL successfully

From 2019 Jun attended the tender, and win this order from more than 10 suppliers, Hebei Haihao Group finished SNGPL tender No.SND-2074/19 flange order successfully. As known,Sui Northern Gas Pipelines Limited (SNGPL) was incorporated as a private limited Company in 1963 and converted into a pub ...

-

What’s the preheating treatment of flange?

The heat treatment of pipe fittings and flanges is more and more widely used in industry. The function of heat treatment is to improve the mechanical properties of materials, eliminate residual stress and improve metal cutting processability. According to different purposes of heat treatment, he ...

-

What’s the standard system of flange?

Hebei Haihao Group is one of the leading manufacturers for pipe fittings and Flanges. We have focused on this filed for almost 40 years and has established good relationships with many customers all over the world. We can provide good products with high quality according to the customers’ ...

-

Correct packing and shipping is an important step for piping products

Imagine the time and effort wasted when you sent out one inquiry after another, compared one offer after another, and finally chose a company to work with. But when you receive the goods only to find that the goods are missing, damaged, the production does not meet the expected standards, which ...

-

The Spanish customer ordered large size flanges

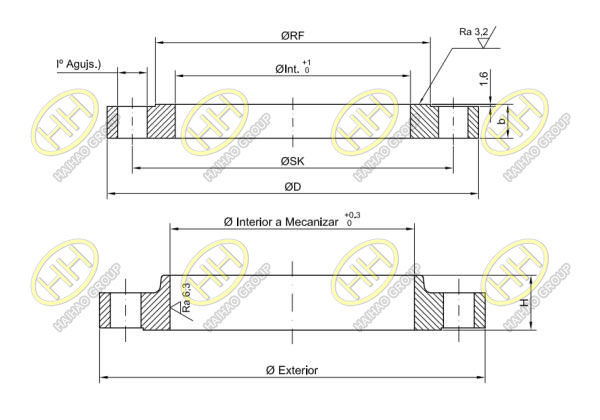

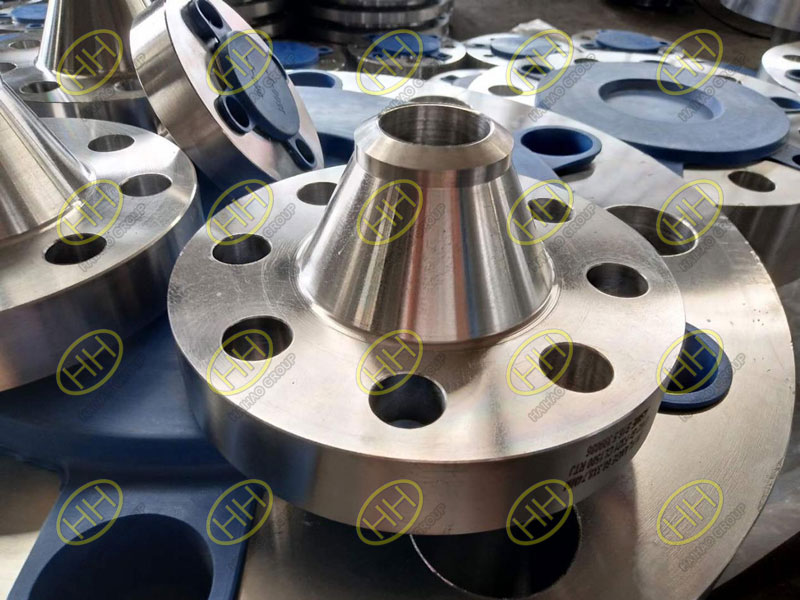

I have a Spanish client who has placed an order with us for large size flanges. The materials of the order are 316L and S275JR. The drawing as below: Large size flange drawing Large diameter flange for flange and pipe welding, mainly used in welding technology, good performance of the use of cha ...

-

Kazakhstan – insulation flange order

Insulation joint is an improved replacement product based on the problems existing in the use of insulation flange. It is an important element of pressure and is essential to the cathodic protection system of steel pipes. It is widely used in the cathodic protection system of steel pipes. Insula ...

-

What’s orifice flange and the type of orifice flange?

Hebei Haihao Group is one of the leading pipeline material manufacturer in China. We are specialized in carbon steel, stainless steel and alloy steel flange, fittings and pipe. Here we introduce one kind of flange – Orifice flange ANSI ASME B16.36 orifice flange General Description ANSI/AS ...

-

Stainless steel flanges are ready for shipment to Egypt

After nearly two months of production, a batch of stainless steel flange production was completed. After the inspection by the quality inspection department of the factory, all the data are qualified and ready to be sent to Egypt today. ANSI/ASME B16.5 304 raised face plain flanges One day more ...

-

Heat treatment technology of Weld-neck flange

Weld-neck flange is a kind of pipe fittings, which refers to the flange with neck and transition of round pipe and Weld-neck connection with pipe. Weld-neck flange with neck is a kind of steel hot pressed or forged flange. Its connection form is directly Weld-neck the flange and steel pipe. The ...