-

Hot dip galvanized flange and cold galvanized flange main difference

Obviously, the two galvanizing processes are used at different temperatures and different galvanizing processes. The processing process of hot-dip galvanized flange is, first of all, the flange is immersed in the temperature of 440-465℃ in the process of processing of molten zinc, iron matrix an ...

-

Advantages of galvanized flange

In the production of flange, because of the low cost of carbon steel flange, anti-corrosion performance is far less than stainless steel, alloy steel and other materials of flange superior, often use cold galvanized and hot galvanized these two processing methods, to improve the anti-corrosion p ...

-

Why should the flange be galvanized?

Flange is an interconnected part between shafts, which is used to connect pipe ends. It is an important part type in chemical production pipeline system. The quality of flange will directly affect the sealing performance of flange connection. The quality depends on the flange material and the pr ...

-

Slip on flange is being shipped to Singapore

About two months ago, a customer from Singapore ordered a batch of slip on flanges. The size is 1″ ~12″, the pressure is 150LB and 300LB, the material is ASTM A105, the standard is ASME B16.5. As the customer have special requirements for the marking, they require marking content to ...

-

The delivery of Figure-8 flange

Today, the 10″ 900# SS316 figure-8 flanges were deliveried. Figure-8 flange is a kind of flange, because its shape like “8”, so called Figure-8 Blank. It is one end of the blind flange, the other end is composed of throttling ring, in the transmission of fluid, the use of throt ...

-

Exported JIS B2220 SS304 SOH flanges to India

Some time ago,we exported a batch of JIS B2220 SOH flanges made of SS304 to India.We not only completed these flanges quickly, but also carried out strict size and marking inspection on these goods.Each flange was protected with a plastic sheath and packed in wooden case.The customer was very sa ...

-

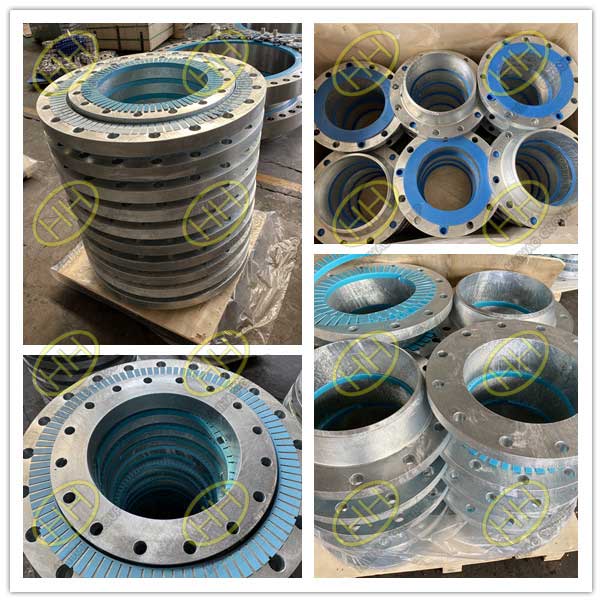

The delivery of plastic coated slip on flange

We have recently completed a batch of orders slip on lining plastic flanges, the customer request the material of slip on flange is A105, the size is 3′-6′, pressure is 300 #, inner and outer wall coated with polymer material.The coating material is polyethylene (PE), crosslinked pol ...

-

Order of drawing flanges

Recently we received an inquiry from a customer in Spain. The inquiry content is carbon steel flanges, but all flanges are customized flanges from drawings. The customer is an old customer we have cooperated with before. The customer often purchases customized flanges with some drawings. Soon ...

-

Win the customer’s trust, the end of the flange order is a new beginning

Half a month ago, 63 pieces of stainless steel large-size flange have been shipped, and now the customer has received the goods. The customer received the goods as expected, very satisfied. Since we arranged production from the initial inquiry to the customer’s order, the inspection was ve ...

-

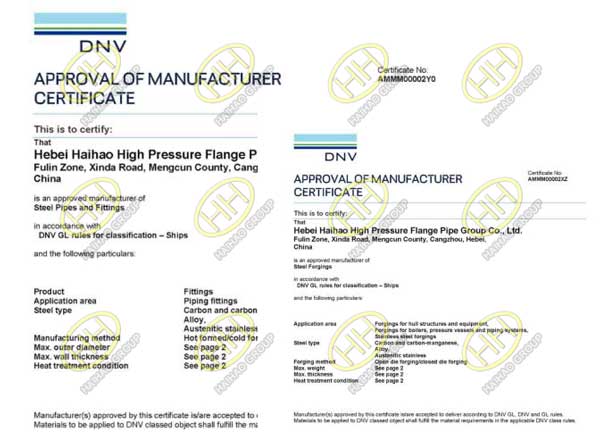

Hebei Haihao Group has received the DNV certification

Recently, the carbon steel, alloy steel and stainless steel flange,pipe fittings produced by Hebei Haihao Group have obtained the certification of DNV and the relevant certificates approved and issued by the headquarters of DNV. This is another classification society certification obtained by He ...

-

The delivery of stainless steel large size flanges has been arranged

Production and inspection of 63 stainless steel large-size flanges have been completed, and the customer has arranged shipment. In order to ensure that the products will not be damaged during transportation, although the total weight of the products is only about 12 tons, we also ordered a 20-fo ...

-

The customer arranges a third party TUV to inspect the flanges in the factory

The Indian customer ordered 63 pieces of large-size stainless steel flanges. Since the customer is in a hurry to deliver the goods, we have finished the production within the delivery period and finished the inspection by ourselves. Therefore, we inform the customer to arrange a third party to i ...