-

Common types of stainless flanges

The function of welded steel stainless steel flange is to butt weld the flange and pipe. The structure is reasonable, the compressive strength is high, the bending stiffness is large, and it can withstand ultra-high pressure, continuous bending and temperature fluctuations, and the sealing perfo ...

-

Relevant knowledge of flange gasket

The gasket is a ring made of a material that can produce plastic deformation and has a certain strength. Most gaskets are cut from non-metallic plates, or made by professional factories according to the specified standards. Their materials are asbestos rubber sheets, asbestos sheets, PTFE sheets ...

-

Flange welding skills

With the increasing demand for prefabrication in the market, each factory is facing more challenges. In addition to the production of products, the factory still needs to master more technology to complete the assembly of products before leaving the factory. The assembly of pipe fittings cannot ...

-

What is a large diameter flange?

Large diameter flange is one of the flanges. It refers to the flange that exceeds the size specified by the relevant national departments, and generally refers to the flange above DN2000. It is widely used and promoted in the machinery industry, chemical industry, wind power industry, and sewage ...

-

Application difference of flanges under petrochemical standard classification

According to petrochemical standards, flanges can generally be divided into the following five types: flat welding flange, butt welding flange, socket welding flange, loose sleeve flange and threaded flange. The flat welding flange is simple in structure and uses less materials when making, but ...

-

Classification of flanges

Flange is a connecting part. According to different standards, there are different classifications. Let’s learn about them together. According to the chemical industry standards, it is divided into integral flange, threaded flange, plate type flat welding flange, neck butt welding flange, ...

-

What causes flange leakage

There are seven common reasons for flange leakage: 1.The pipeline and flange are not vertical and concentric, and the flange surface is not parallel. When the internal medium pressure exceeds the load pressure of the gasket, flange leakage will occur. 2.The pipe and flange are vertical, but the ...

-

Large flange for wind power generation

The global wind power industry has a history of more than 40 years. With the global energy structure changing to low-carbon and the energy consumption structure continuously optimizing, wind power as a renewable energy, has developed rapidly in recent years and the global wind power installed ca ...

-

Introduction of anchor flange

We received an inquiry from a Dutch customer this week about various standard flanges, among which one of the customers needs anchor flanges. The anchor flange has been reported to the customer many times before. Today, let’s learn about anchor flange. Anchoring flange is the key part of l ...

-

Introduction of surfacing welding

For steel products such as steel pipes and pipe fittings, welding is the key point to ensure quality in the production process, and it is also the place that all pipe fittings manufacturers attach importance to. The mature welding process can guarantee the quality of the weld, thus ensuring that ...

-

Knowledge of cast flanges and forged flanges

Flange production processes mainly include forging, casting, cutting and rolling. Different processes can produce products with different performance. Today, let’s take a look at the differences between the two flange processes – casting and forging. EN 1092 1 forged slip on flanges ...

-

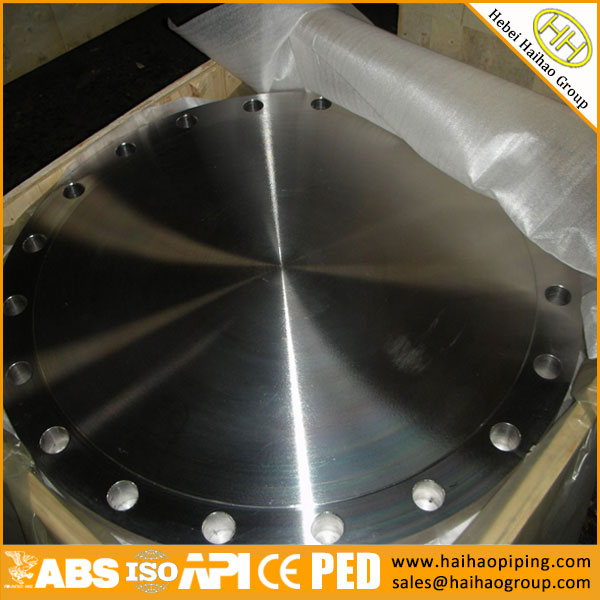

A105N blind flanges and weld neck flanges sent to Singapore shipyard

Hebei Haihao Group has produced flanges for more than 40 years. We have a professional team and technical personnel, the pursuit of high-quality products. In February this year, our Singapore customer purchased weld neck flanges and blind flanges made of ASTM A105N from us, which needs ABS certi ...