-

What are the causes of flange leakage?

This week, we received a complaint from a customer about another supplier. The flange we bought from another supplier was leaked. We would like to ask for our inquiry and purchase again. Today, let’s take a look at the causes of flange leakage 1.Wrong mouth, refers to the pipe and flange a ...

-

Wind power flange manufacturing technology

Wind power flange is a structural member connecting each section of tower or between tower and hub, hub and blade, which is usually connected by bolts. Wind power flange is also called wind tower flange, and its process mainly includes the following steps: Source of raw material refining export ...

-

Forging process of weld neck flange

Weld neck flange is a kind of pipe fittings, which refers to the flange with neck and transition of round pipe and weld neck connection with pipe. Weld neck flange is not easy to deform, well sealed and widely used. It has corresponding rigid and elastic requirements and reasonable weld neck thi ...

-

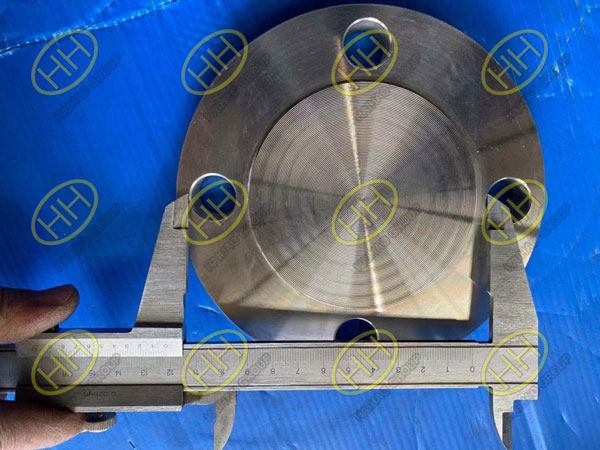

The Colombian customer ordered large size flanges

As shown in the figure, 32-inch weld neck(WN) RF flange, 300#, material A105, according to the standard ASME B16.47A, the customer placed an order in early May, and it is expected to be delivered to Colombia in early June, which is used in the construction and use of large pipelines. Markings ar ...

-

Laser cutting method of weld neck flange

Weld neck flange is a kind of pipe fittings, which refers to the flange with neck and transition of round pipe and Welding-Neck connection with pipe. Weld neck flange is not easy to deform, well sealed and widely used. It has corresponding rigid and elastic requirements and reasonable weld neck ...

-

The process characteristics and functions of large diameter flange

Large diameter flange is a kind of flange, which is widely used and promoted in the machinery industry. The flange made in our factory has been praised and loved by users. Large diameter flange materials are carbon steel, stainless steel, alloy steel, etc. Large diameter flange is widely used, a ...

-

Cancel the export tax rebate of some steel products, is it good or bad for the steel industry?

Tariffs on some steel products will be adjusted from May 1, 2021, according to a notice posted on the website of the Ministry of Finance.Among them, pig iron, crude steel, recycled steel raw materials, ferrochrome and other products to implement zero import tariff rate;We will appropriately rais ...

-

Characteristics and installation of blind flange

Blind flange is commonly known as flange cover and blind plate (BL flange). The blind flange is similar to a steel plate edge drilling, because there is no inner hole in the middle, so it becomes a blind flange. Its connection mode is to connect with the flange, and its main function is to block ...

-

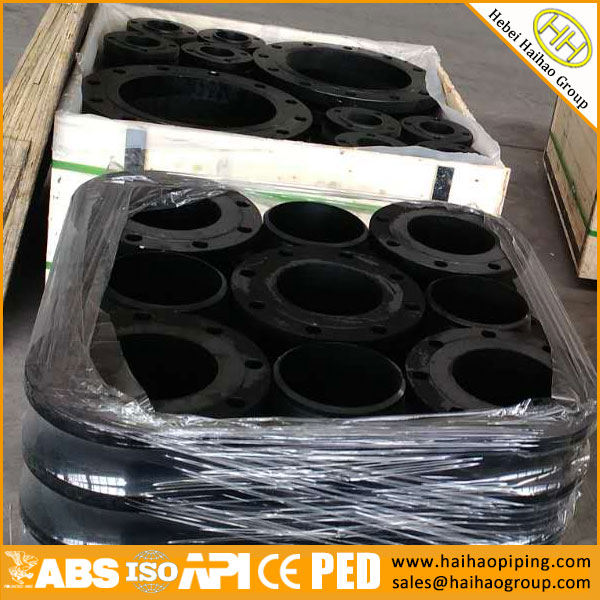

P245GH flanges to Singapore shipyard

As shown in the figure, our company recently produced a batch of P245GH flanges. After strict quality and production control and solid packaging, we ordered a ship to be shipped to Singapore before the May Day holiday. According to the communication from the customer, this batch of high quality ...

-

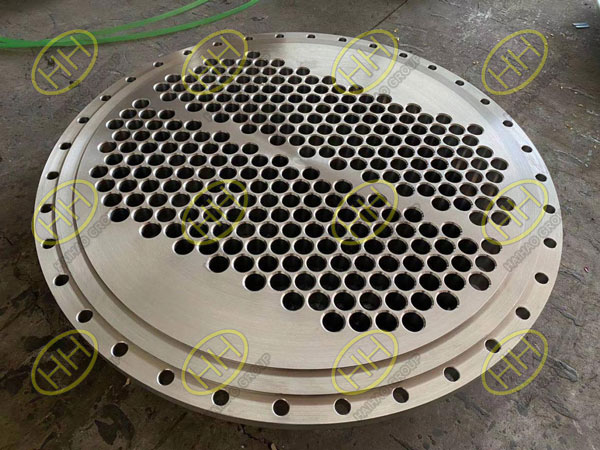

What is the Tubesheet?

Tubesheet is a kind of round steel, which is used to fix the tube and seal the medium in the heat exchanger. It is a kind of fitting which can weld and fix the pipe. The precision of tubesheet processing, especially the pipe hole spacing and pipe diameter tolerance, perpendicularity and finish, ...

-

Hot dip galvanizing for flange

Hot dip galvanizing is an effective way of metal anticorrosion. Flanges hot dip galvanizing refers to the production of flange molding, after rust immersed in the molten zinc at about 500 degrees Celsius, so that the surface of the flange steel member is attached to zinc layer, so as to achieve ...

-

How to clean the carbon steel flange?

Once the flange appears rust or the surface of the flange stains, it will cause damage to the flange itself, and may even affect the entire pipeline transport, so that the pipeline leakage. Carbon steel flanges may have cleaning problems after tempering during heat treatment. For example, improp ...