Why should the flange be galvanized?

Flange is an interconnected part between shafts, which is used to connect pipe ends. It is an important part type in chemical production pipeline system. The quality of flange will directly affect the sealing performance of flange connection. The quality depends on the flange material and the processing method in flange production. I don’t know if you have found that many standard flanges need galvanizing treatment before leaving the factory. Why galvanizing treatment? Now let me reveal the secret for you!

Far less than the corrosion resistance of stainless steel, alloy steel and other materials, but the cost of carbon steel flange is low. In order to achieve corrosion resistance and prolong its service life, it can also save cost. Galvanizing method is usually used.

So what are the advantages of flange galvanizing?

Advantage 1: flange galvanizing can make every part of the coating galvanized, and the galvanized layer forms a special metallurgical structure. Even if the flange galvanizing is mechanically damaged during transportation and use, the structure will not have much impact. In the groove, sharp corners and hidden positions can also be completely protected, so the durability of the coating is more reliable; The standard hot-dip galvanized antirust thickness can be maintained for more than 50 years without maintenance in suburban environment; In urban or offshore areas, standard hot-dip galvanized anti-corrosion coatings can be maintained for 20 years without maintenance.

Advantage 2: the galvanizing process can avoid the time required for on-site spraying after installation, and the cost of hot-dip galvanizing is relatively low. Of course, the galvanizing process is faster than other coatings.

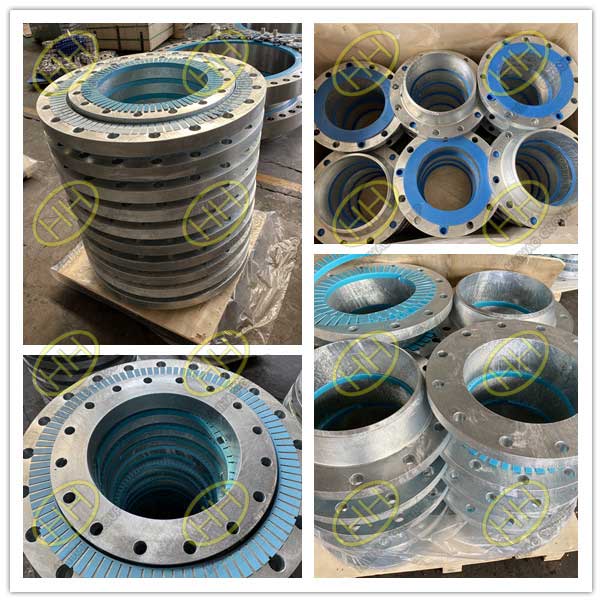

Recently, we received an order from our Dutch customer. The customer requires the flange to be galvanized, and the specifications are as follows.

| Description | Qty |

| 12 in Slip on flange CL 150 FF,CS A105HDG Dims to ASME B16.5 | 42 |

| 18 in Slip on flange CL 150 FF,CS A105HDG Dims to ASME B16.5 | 76 |

| 18 in Blind flange CL 150 FF,CS A105HDG Dims to ASME B16.5 | 1 |

| 14 in Slip on flange CL 150 FF,CS A105HDG Dims to ASME B16.5 | 40 |

| 14 in STD Weld neck flange CL 150 FF,CS A105HDG Dims to ASME B16.5 | 2 |

| 2 in Threaded flange ASME B1.20.1(NPT) Fem CL 150 FF CS A105HDG Dims to ASME B16.5 | 11 |

| 3 in Threaded flange ASME B1.20.1(NPT) Fem CL 150 FF CS A105HDG Dims to ASME B16.5 | 2 |

| 4 in Threaded flange ASME B1.20.1(NPT) Fem CL 150 FF CS A105HDG Dims to ASME B16.5 | 12 |

| 4 in Blind flange CL150 FF,CS A105HDG Dims to ASME B16.5 | 1 |

| 2 in Blind flange CL150 FF,CS A105HDG Dims to ASME B16.5 | 6 |

| 6 in Slip on flange CL150 FF CS A105HDG Dims to ASME B16.5 | 13 |

| 10 in STD Weld neck flange CL150 FF CS A105HDG Dims to ASME B16.5 | 36 |

| 12 in STD Weld neck flange CL150 FF CS A105HDG Dims to ASME B16.5 | 18 |

| 16 in Blind flange CL150 FF,CS A105HDG Dims to ASME B16.5 | 3 |

| 16 in Slip on flange CL150 FF CS A105HDG Dims to ASME B16.5 | 222 |

| 14 in STD Weld neck flange CL150 FF CS A105HDG Dims to ASME B16.5 | 18 |

| 24 in Slip on flange CL150 FF CS A105HDG Dims to ASME B16.5 | 81 |

After customer acceptance, all products are qualified and appreciated by customers.