-

Method of flange connection

Flange connection consists of a pair of flanges, a gasket and a number of bolts and nuts. Flanges with holes, can wear bolts, so that the two flanges are tightly connected, between the flanges with gasket sealing. The gasket is placed between the sealing surface of two flanges. After the nut is ...

-

What are the common obstacles of flange?

If the problem of flange leakage can not be handled in time, the leakage will expand rapidly under the medium corrosion, form data loss, damage the production environment, make the enterprise stop production, and form huge economic losses. If the accident is the leakage of toxic, flammable and e ...

-

Spectacle blind flange ASME B16.5

Spectacle blind flange ASME B16.5 is designed to isolate or connect piping systems.It consists of two discs connected by flat steel, one is solid and the other hollow ring with the same diameter as the flange.Spectacle blind flange ASME B16.5 is independent of other facilities or equipment in t ...

-

Corrosion of stainless steel flange

Stainless steel flange has the ability of corrosion in the medium containing acid, alkali and salt, namely corrosivity; it also has the ability of anti atmospheric oxidation, namely, rust resistance; however, the size of its corrosion ability varies with the chemical composition of the steel its ...

-

How to prevent rust of large stainless steel butt welding flange?

As a sealing and fastening connector, large diameter flange is easy to install, flexible in position and long in service life. It is widely used in large vessels in aerospace, petroleum, chemical and other fields. The welding seam of large diameter flange shall be subject to 100% ultrasonic or r ...

-

What is an anchor flange?

An anchor flange is a device installed on a pipeline to combat axial movement. Resembling a collar, once it is attached to a pipe, the anchor flange is commonly anchored into a concrete foundation. Typically placed onto a section of pipeline as it makes a turn or is at a bridge crossing, the anc ...

-

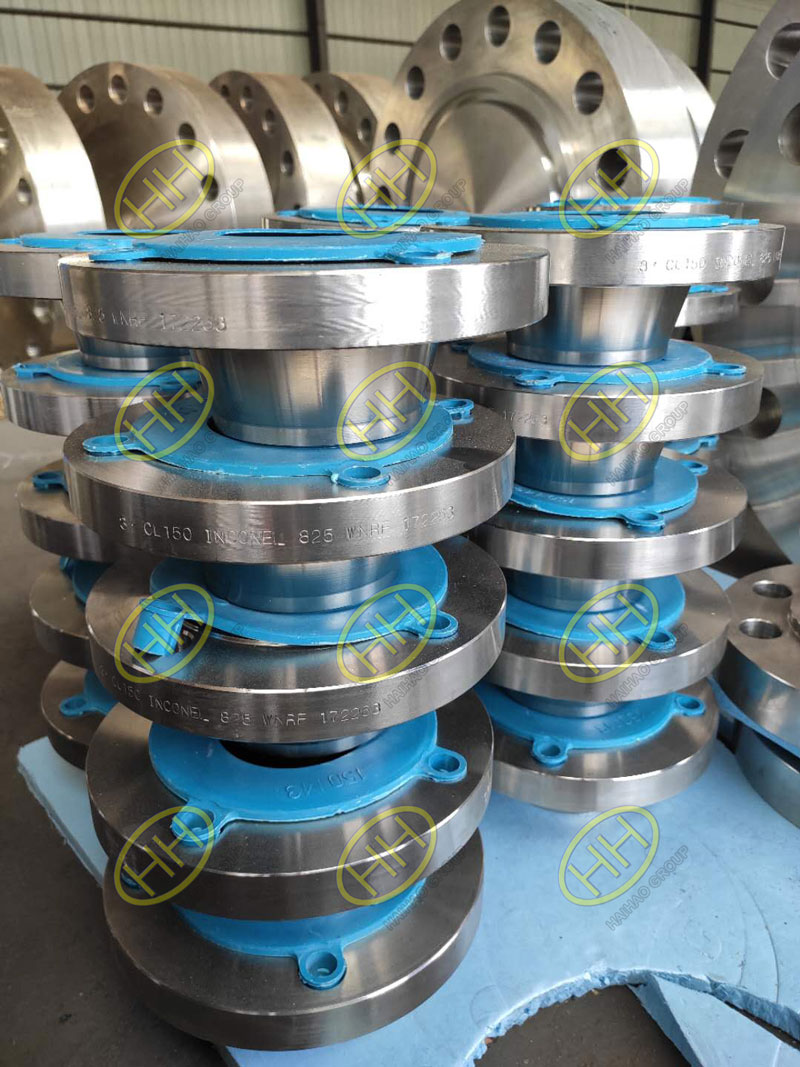

Production process of forged flange and cast flange

Flange is a kind of connection sealing parts. If there are quality problems in the production process, there will be leakage, resulting in economic losses, environmental damage and even safety accidents. So the welding and production of flange is very important. At present, the flange production ...

-

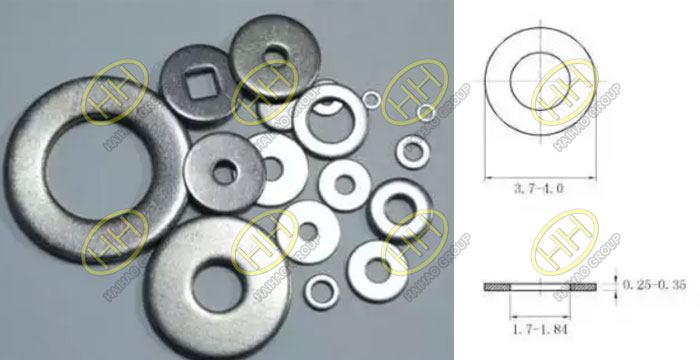

What’s the difference between the spring washers and flat washers?

Flat washers and spring washers are well-known and frequently used washers. Due to the different characteristics of the two,in actual application,the two must be distinguished, otherwise not only cannot play the role of the gasket,but may cause some unnecessary trouble. As the professional flang ...

-

The factors affect the sealing performance of pressure vessel flanges

The tightness of the pressure vessel flange will be affected by the bolt pretension,gasket sealing performance,flange sealing surface characteristics,flange stiffness and operating conditions during use. 1.Bolt pre-tightening force Appropriate pre-tightening force can ensure that the gasket can ...

-

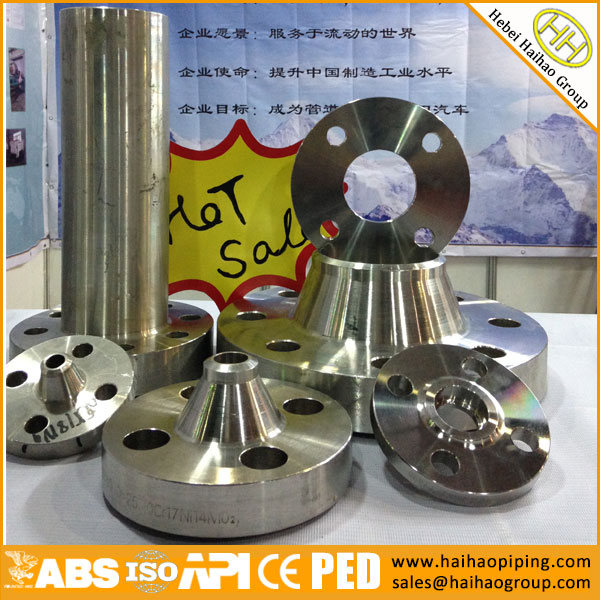

The larger the quantity of flanges, the more competitive the price

Purchasing is one of the most basic needs of people’s lives. Purchasing generates buyers and sellers. However, buyers and sellers have different starting points and interests in the process of commodity exchange. Most buyers are pursuing better prices, while sellers are pursuing greater pr ...

-

Flanges painting with red oxide primer

Red oxide primer is a specially formulated coating used as a base coat for ferrous metals. Red-oxide primer serves a similar purpose to interior wall primers in that it prepares your metal for a topcoat, but it also gives iron and steel surfaces a layer of protection. Working with red oxide prim ...

-

What’s the production precautions of stainless steel flanges?

First, stainless steel flanges should be away from corrosion of stainless steel materials.For stainless steel flanges, it is most important to keep the flange surface clean.Once the surface of the stainless steel flange is corroded, the appearance of the stainless steel flange will change, no lo ...