-

Classification of flanges

Flange is a connecting part. According to different standards, there are different classifications. Let’s learn about them together. According to the chemical industry standards, it is divided into integral flange, threaded flange, plate type flat welding flange, neck butt welding flange, ...

-

What causes flange leakage

There are seven common reasons for flange leakage: 1.The pipeline and flange are not vertical and concentric, and the flange surface is not parallel. When the internal medium pressure exceeds the load pressure of the gasket, flange leakage will occur. 2.The pipe and flange are vertical, but the ...

-

Large flange for wind power generation

The global wind power industry has a history of more than 40 years. With the global energy structure changing to low-carbon and the energy consumption structure continuously optimizing, wind power as a renewable energy, has developed rapidly in recent years and the global wind power installed ca ...

-

Introduction of anchor flange

We received an inquiry from a Dutch customer this week about various standard flanges, among which one of the customers needs anchor flanges. The anchor flange has been reported to the customer many times before. Today, let’s learn about anchor flange. Anchoring flange is the key part of l ...

-

Introduction of surfacing welding

For steel products such as steel pipes and pipe fittings, welding is the key point to ensure quality in the production process, and it is also the place that all pipe fittings manufacturers attach importance to. The mature welding process can guarantee the quality of the weld, thus ensuring that ...

-

Knowledge of cast flanges and forged flanges

Flange production processes mainly include forging, casting, cutting and rolling. Different processes can produce products with different performance. Today, let’s take a look at the differences between the two flange processes – casting and forging. EN 1092 1 forged slip on flanges ...

-

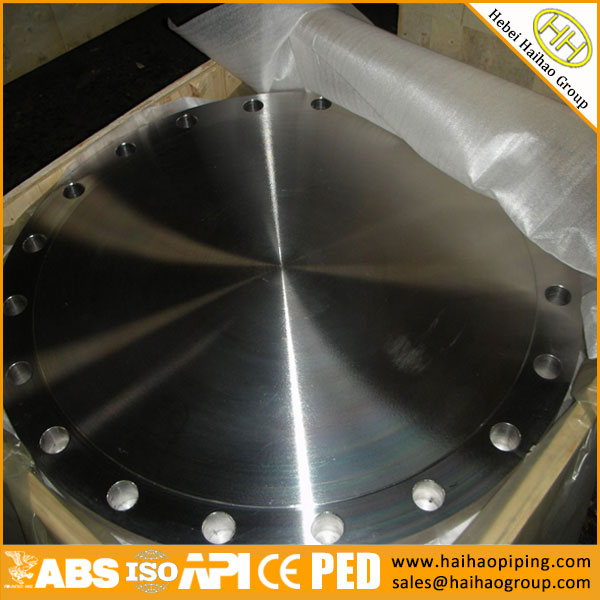

A105N blind flanges and weld neck flanges sent to Singapore shipyard

Hebei Haihao Group has produced flanges for more than 40 years. We have a professional team and technical personnel, the pursuit of high-quality products. In February this year, our Singapore customer purchased weld neck flanges and blind flanges made of ASTM A105N from us, which needs ABS certi ...

-

What factors affect the sealing performance of pressure vessel flanges?

The tightness of the pressure vessel flange will be affected by the bolt pretension, gasket sealing performance, flange sealing surface characteristics, flange stiffness and operating conditions during use. Let me take a closer look. 1.Bolt pre-tightening force Appropriate pre-tightening force c ...

-

Safe and efficient transportation enables you to receive the goods as soon as possible

Imagine the time and effort wasted when you sent out one inquiry after another, compared one offer after another, and finally chose a company to work with. But when you receive the goods only to find that the goods are missing, damaged, the production does not meet the expected standards, which ...

-

Order for complete flanges in Russia

The following are the order from old Russian customers in June. The general product description is for example: Set of companion flanges, gaskets, bolts and nuts, consist of: 2 x weld neck flanges ASME B16.5 (DN 3″, Pressure class: ANSI 300, material: A182 F9), 2 x Gaskets (SWG, 304SS/Grap ...

-

What is ZPS washer and HCS washer?

In the previous articles, the main product types of insulation kits are basically introduced. Finally, it is worth noting that it was mentioned in the initial introduction to the components of the insulation kit, “3. Steel Washer: ZPS Washer;” and “4. Insulating Washer: HCS Washer.” The HCS was ...

-

What is LPG gasket?

HPG gasket was introduced in the previous article, and then let’s learn about the light green LPG gasket. In fact, from the comparison of these two type pictures, we can found that the black HGP is thicker, while the light green LGP is lighter. Light green LPG gasket LPG system is an insul ...