ANSI/ AMSE B16.5 class 150 socket weld flange

ANSI/ASME B16.5 standard covers pressure,temperature,ratings,materials,dimensions,tolerances,marking, testing,and methods of designating openings for pipe flanges and flanged fittings.Socket weld flange dimensions are covered in ANSI/ASME B16.5 for size NPS ½” to 3″.

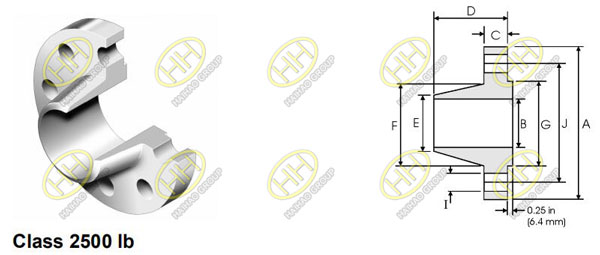

ANSI/ AMSE B16.5 class 150 socket weld flange dimensions:

| Pipe |

Flange |

Hub |

Raised Face |

Drilling Data |

Weight |

||||||||

| Nominal Pipe Size | A | B | C | D | E | K | F | G | H | I | J | ||

| Outside Diameter | Overall Diameter | Inside Diameter | Flange Thickness min | Overall Length | Socket Diameter | Depth of Socket | Hub Diameter | Face Diameter | No. of Holes | Bolt Hole Diameter | Diameter of Circle of Holes | kg/piece | |

| in mm |

in mm |

in mm |

in mm |

in mm |

in mm |

in mm |

in mm |

in mm |

in mm |

in mm |

|||

| ½ | 0.840 21.30 | 3.500 88.90 | 0.620 15.70 | 0.440 11.20 |

0.620 15.70 | 0.880 22.40 | 0.380 9.600 | 1.190 30.20 | 1.380 35.10 | 4 | 0.620 15.70 | 2.380 60.45 | 0.42 |

| ¾ | 1.050 26.70 | 3.880 98.60 | 0.820 20.80 | 0.500 12.70 |

0.620 15.70 | 1.090 27.70 | 0.440 11.10 | 1.500 38.10 | 1.690 42.90 | 4 | 0.620 15.70 | 2.750 69.85 | 0.59 |

| 1 | 1.315 33.40 | 4.250 108.0 | 1.050 26.70 | 0.560 14.20 |

0.690 17.50 | 1.360 34.50 | 0.500 12.70 | 1.940 49.30 | 2.000 50.80 | 4 | 0.620 15.70 | 3.120 79.25 | 0.81 |

| 1 ¼ | 1.660 42.20 | 4.620 117.3 | 1.380 35.10 | 0.620 15.70 |

0.810 20.60 | 1.700 43.20 | 0.560 14.20 | 2.310 58.70 | 2.500 63.50 | 4 | 0.620 15.70 | 3.500 88.90 | 1.07 |

| 1 ½ | 1.900 48.30 | 5.000 127.0 | 1.610 40.90 | 0.690 17.50 |

0.880 22.30 | 1.950 49.50 | 0.620 15.70 | 2.560 65.00 | 2.880 73.15 | 4 | 0.620 15.70 | 3.880 98.60 | 1.36 |

| 2 | 2.375 60.30 | 6.000 152.4 | 2.070 52.60 | 0.750 19.10 |

1.000 25.40 | 2.440 62.00 | 0.690 17.50 | 3.060 77.70 | 3.620 91.90 | 4 | 0.750 19.10 | 4.750 120.7 | 2.10 |

| 2 ½ | 2.875 73.00 | 7.000 177.8 | 2.470 62.70 | 0.880 22.40 |

1.120 28.40 | 2.940 74.70 | 0.750 19.00 | 3.560 90.40 | 4.120 104.6 | 4 | 0.750 19.10 | 5.500 139.7 | 3.33 |

| 3 | 3.500 88.90 | 7.500 190.5 | 3.070 78.00 | 0.940 23.90 |

1.190 30.20 | 3.570 90.70 | 0.810 20.60 | 4.250 108.0 | 5.000 127.0 | 4 | 0.750 19.10 |

6.000 152.4 |

3.90 |

Notes:

- Dimension B corresponds to the pipe inside diameter. Values quoted assume 40S/Standard wall thickness.

- Weights are based on manufacturer’s data and are approximate.

Specifications of ANSI/ASME B16.5 flange:

Types of ANSI/ASME B16.5 forged flanges:

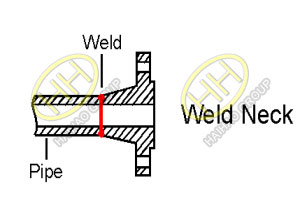

| Weld neck flange(WN flange) is circumferentially welded into the system at its neck which means that the integrity of the butt welded area can be easily examined by radiography.The bores of both pipe and flange match,which reduces turbulence and erosion inside the pipeline.The weld neck is therefore favoured in critical applications. |

|

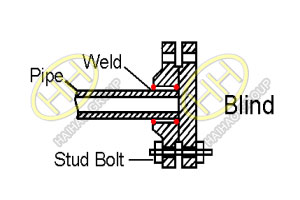

| Blind flange is used to blank off pipelines,valves and pumps,it can also be used as an inspection cover.It is sometimes referred to as a blank flange. | |

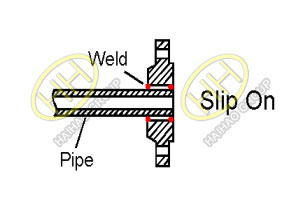

| Slip on flange(SO flange) is slipped over the pipe and then fillet welded.Slip-on flanges are easy to use in fabricated applications. | |

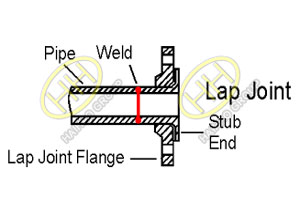

| Lap joint flange(LJ flange) is always used with either a stub end or taft which is butt welded to the pipe with the flange loose behind it.This means the stub end or taft always makes the face.The lap joint is favoured in low pressure applications because it is easily assembled and aligned.To reduce cost these flanges can be supplied without a hub and/or in treated,coated carbon steel. |

|

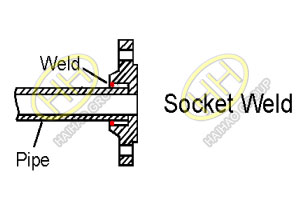

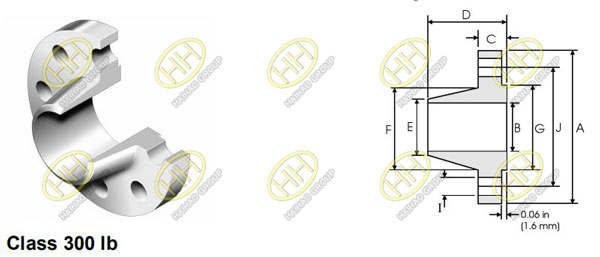

| Socket weld flange(SW flange) is counter bored to accept the pipe before being fillet welded.The bore of the pipe and flange are both the same therefore giving good flow characteristics. | |

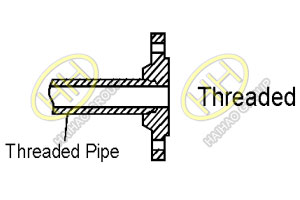

| Threaded flange is referred to as either threaded or screwed.It is used to connect other threaded components in low pressure, non-critical applications.No welding is required. | |

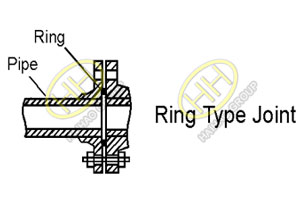

| Ring type joint is a method of ensuring leak proof flange connection at high pressures.A metal ring is compressed into a hexagonal groove on the face of the flange to make the seal.This jointing method can be employed on weld neck flanges,slip on flange and blind flanges. |

Materials of ANSI/ASME B16.5 class 150 socket weld flange:

Carbon steel ANSI/ASME B16.5 socket weld flange:

ASTM A105,A350 LF2,SS400,P235GH,P250GH,C22.8,Q235,20#,16Mn,etc.

Stainless steel ANSI/ASME B16.5 socket weld flange:

ASTM A182 F304,F304L,F316,F316L,F321,F347,F310,F44,F51,etc.

Alloy steel ANSI/ASME B16.5 socket weld flange:

ASTM A694 F42,F46,F52,F56,F60,F65,F70,A182 F5,F9,F91,F12,F11,F22,etc.

Related:

- ANSI/ASME B16.5 class 150 socket weld flange

- ANSI/ASME B16.5 class 300 socket weld flange

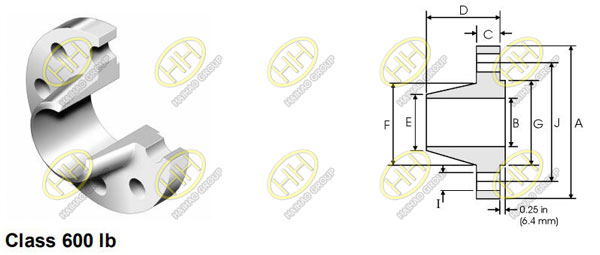

- ANSI/ASME B16.5 class 600 socket weld flange

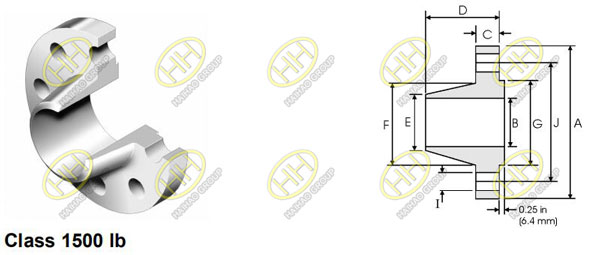

- ANSI/ASME B16.5 class 1500 socket weld flange

Haihao Group is one of the the biggest flanges manufacturer & supplier & exporter in China,we has strong experience in flange production and inspection and a complete set of equipments,including advanced cutting,forging,machining,drilling machines and professional testing & inspection instruments.If you want to know more about our forged flanges,please email us:sales@haihaogroup.com