-

Assembly method of copper flange

1.When installing the connecting pipe flange on the vertical cylinder, first, ensure that the cylinder end surface unevenness meets the requirements, and then adjust the cylinder end surface horizontally to ensure that the cylinder is vertical. Draw a reference circle outside the opening line (t ...

-

How to divide the pressure rating of common flange?

In the domestic and international standards, there are clear requirements for the compression resistance of large stainless steel flange. Large stainless steel flange is generally divided into PN25, pn6, PN10, PN16, PN25, PN40, etc. PN10 and PN16 are commonly used. GOST/ГОСТ 12821-80 FLANGE PN4. ...

-

What is the difference between the flange pressure class and schedule?

To answer this question, you should know about the flange rating. You must have heard about 150 class flange or 300 class or 600 class flanges. What is this class? Flange class is a combination of pressure-temperature rating that defines maximum allowable working gauge pressure of the flange. He ...

-

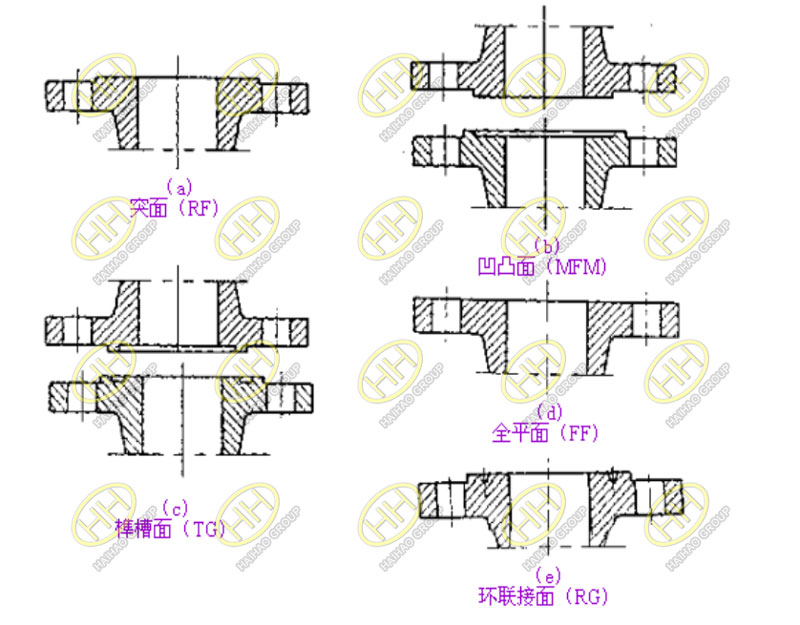

What types of flange sealing surface are available?

Flange connections are rarely damaged due to insufficient strength,but often leak due to poor sealing.Therefore,the sealing problem has become the main problem in flange connection,and the sealing surface and gasket of flange directly affect the sealing of flange,so it is necessary to introduce ...

-

How to deal with the surface damage of large stainless steel flange?

Flange de-rusting method: immerse the flange in hydrochloric acid, the principle is to reduce the rust to iron, but there are dangers in this method. Hydrochloric acid is a corrosive substance, which is harmful to human body. During operation, pay attention not to touch the human body, and neutr ...

-

What are the flange sealing surfaces?

Flange sealing surface includes full face FF, raised face RF, raised face m, concave face FM, tenon face t, groove face g and ring connection face RJ. Generally, the concave convex surface MF, the tenon groove surface TG and the ring connecting surface RJ are used in pairs. Ring groove surface s ...

-

Standard and selection of stainless steel flanges

Stainless steel flanges are mainly made of two kinds of flat welding flange and butt welding flange, each with rings and rings. When flange dimensions are used to determine flange dimensions, the nominal diameter and nominal pressure of the flange must be known. The nominal diameter of the flang ...

-

Simple analysis of flange industry

With the development of flange industry, more and more new flanges have been become available. Also, flange has been applied to wider industry areas, such as the petrochemical industry, oil refining industry, nuclear power industry, thermal power industry and so on. Bigger industrial application ...

-

Large diameter flanges order from UAE

The large diameter flanges are used to connect or to block off two very large diameters sized pipes. A Large Diameter flange is a metal ring that is used to connect valves, pipes, pumps and other equipment that is necessary to form pipelines. The Large Diameter flange also allows people to have ...

-

Advantages of large flanges

Large flanges not only have different use values, effects and functions when used, but also have various materials, production processes and processing methods. Thus, we have to pay special attention to the methods of both processing and utilizing large flanges. Large caliber flat flanges used f ...

-

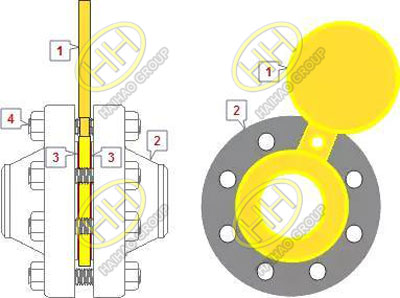

The introduction of figure-8 blank

Figure-8 Blank (Spectacle blind) The Figure-8 Blank gets its name because it looks like an 8-character, also known as spectacle blind. Used to isolate or connect piping systems. The figure-8 blind is a steel plate with a fixed thickness divided into two discs. The two discs are connected by flat ...

-

What’s the difference between butt welding and flat welding in stainless steel flanges?

The difference between the flat welding and the butt welding of the stainless steel flange refers to the two welding methods when the flange is connected with the stainless steel pipe. The flat welding flange welds only one side, without welding the inner mouth of the welded stainless steel pipe ...