-

Sealing principle of flat welding flange

The two sealing faces of the bolt squeeze the flange gasket to form a seal, but this can also cause seal damage.In order to keep the seal,you have to maintain a large bolt force, in order to do this, you have to make the bolt larger. Larger bolts match larger nuts, which means larger bolt diamet ...

-

Connection application of flat welding flange

The smooth flat welding flange is the most widely used. The flat welded steel flange is suitable for the nominal pressure not exceeding 2.5MPa. The carbon steel pipe connection. The sealing surface of the flat welding flange can be made smooth. It is more suitable for medium conditions. In the c ...

-

What is the lap joint flange with welding neck collar?

Lap joint flanges can be mainly divided into four types: loose plate steel pipe flanges with weld-on collar, loose plate steel pipe flanges with welding neck collar, lap joint flanges with welding neck collar and lap joint flanges with welding neck collar. The roles of lap joint flanges: Lap joi ...

-

Common production process for flat welding flange

Common production process for flat welding flange: Round forging process of round steel pure material; Finished forging and cutting forming process; Steel plate cutting and blanking processing technology; Rough forging, expansion machine thermal expansion production process; Steel plate rolling ...

-

Rolling flange processing technology

Rolling flange processing technology: The middle plate is first cut into suitable slivers, and the length of the sliver is determined according to the specifications of the large flange. Then, the ring is rolled into a circle, and the joint is welded firmly with the electrode. Then use the press ...

-

What is a rolled flange?

The rolled flange is cut into slats by the middle plate, and then rolled into a round welded joint and then processed by a flattening process. The coil is made up of cold and hot coils. After processing into a circle, the water line, bolt holes, and stops are processed. This is generally a large ...

-

Packing type of flange, pipe fitting and steel pipe

We will pack the goods before they are shipped,packing plays an import role,can protect the product,easy to load and unload. Packing type of pipe fittings and flanges: We usually pack flange and pipe fitting in pallets or plywood cases.Less than 6 inches use plywood cases,more than 6 inches use ...

-

Gasket and bolt used with flange

Gasket and bolt are commonly used with flange,to protect the flange in the pipeline. 1.Gasket Gasket is especially important for the leakproofness of flange joint. The gasket is a compressible plate or ring used for sealing between two surfaces. Gasket materials are widely used to adapt to vario ...

-

Difference between flange class and flange schedule

Maybe you heard of flange class and flange schedule,sometimes confused what flange class and flange schedule is,are they the same? You maybe know a little about flange,flange class is a pressure-temperature rating that defines maximum allowable working pressure of the flange. Flange class is usu ...

-

Why are the price of 317L flanges higher than 316 and 304 flanges?

There are hundreds of different types of stainless steel flanges on the market, which may be difficult to find the perfect metal for your application. In many purchasing processes, the cost of metals is the first consideration rather than the performance of metals, but this is wrong. In some cas ...

-

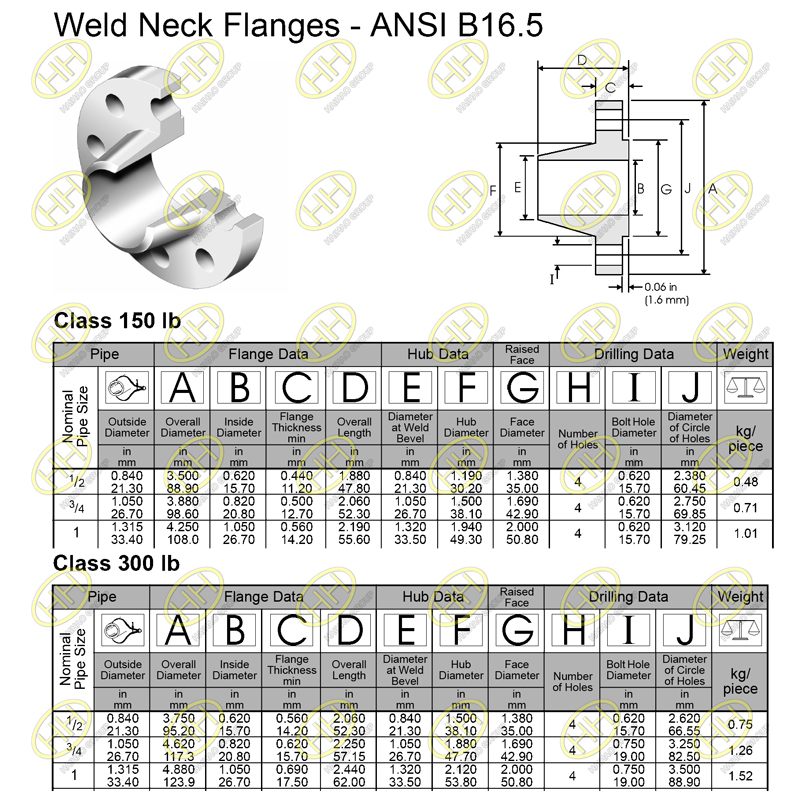

The difference between ASME B16.5 standard and ASME B16.47 standard

What is the difference between ASME B16.5 standard and ASME B16.47 standard? ASME B16.5 standard covers steel pipe flanges and flanged fittings from NPS ½” through NPS 24″ in pressure classes 150 to 2500. This includes pressure ratings, dimensions, tolerances, materials, marking, and ...

-

Production and use requirements of slip on flanges

When producing slip on flanges, steel plates shall not be directly machined into neck flanges, and they shall be fabricated and processed by certain processes. Steel plates for slip-on flanges shall be ultrasonically inspected without delamination defects to ensure good quality and prevent perfo ...