How to Properly Connect Stainless Steel Flanges to Carbon Steel Flanges at High Temperatures

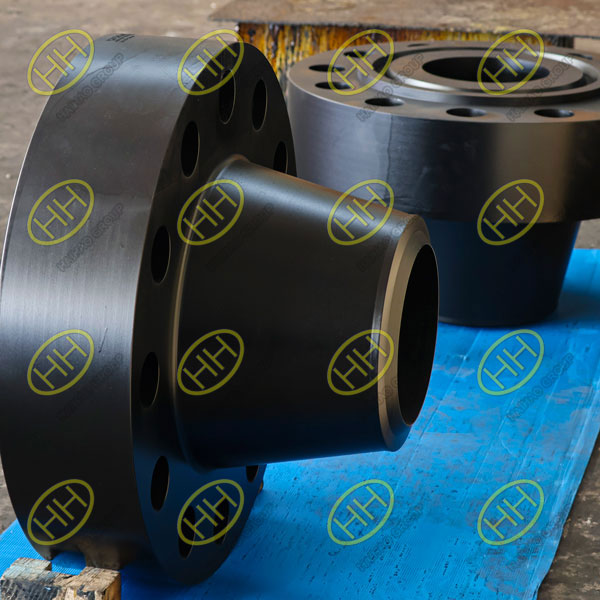

In industrial piping systems, it is generally recommended to avoid mixing different metals—especially stainless steel and carbon steel—due to the risk of galvanic corrosion, thermal stress mismatch, and mechanical incompatibility. However, in many practical scenarios, especially in petrochemical, power generation, and high-temperature process plants, connecting austenitic stainless steel flanges to carbon steel pipelines becomes unavoidable.

To ensure safe, reliable, and long-term operation of such dissimilar metal joints, proper engineering design and installation methods are essential. Below, we explore the best practices for handling stainless steel to carbon steel flange connections under high temperature conditions.

1.Use Stainless Steel Flanges on the Carbon Steel Side

When connecting austenitic stainless steel components (such as a reactor or vessel) to carbon steel piping, the best practice is to use a stainless steel flange on the carbon steel pipe.

The stainless steel flange is directly welded to the carbon steel pipe.

Welding should be done using an appropriate filler material (e.g., E309 or E309L electrode) that can bridge the dissimilar metals and resist thermal fatigue.

This arrangement avoids galvanic corrosion at the bolted flange face, as both mating flanges are stainless steel.

This method is simple and widely adopted for ASME B16.5 or B16.47 flanges in mixed material systems.

2.Design a Transition Piece Between Dissimilar Materials

In more complex systems, such as when a reactor is made of high-alloy stainless steel and the connecting pipe is carbon steel or another alloy, it is recommended to introduce a transition spool piece (also called a transition pipe or intermediate section).

This spool is made by welding together two short pipe sections of the respective materials.

The welds are typically performed using higher-grade filler materials—usually selected based on the higher alloy content to ensure metallurgical compatibility.

The transition spool is then flange-connected or field-welded to the rest of the system.

This technique helps minimize thermal stress, control corrosion, and maintain mechanical integrity across varying metal grades.

3.Match Support Bracket and Clamp Materials to the Pipe

During installation, temporary or permanent supports (such as pipe shoes, guides, or clamps) are often welded to the pipe surface.

These attachments should be of the same material as the pipe or at least metallurgically compatible.

For example, stainless steel pipe should not have carbon steel clamps welded directly onto it, as this can cause stress corrosion cracking and localized failure.

Using matching materials also ensures thermal expansion compatibility, which is crucial in high-temperature piping systems.

4.Prevent Galvanic Corrosion in Bolted Joints

When steel bolts and nuts are used on flanged connections involving aluminum or stainless steel pipes, there’s a risk of galvanic corrosion, especially in humid or marine environments.

To prevent this:

Use insulating washers or sleeves between bolts/nuts and the pipe or flange face.

Materials such as non-metallic gaskets, nylon washers, or PTFE isolators can be used to separate dissimilar metals.

This simple step prevents unwanted electrochemical reactions, which are a leading cause of premature flange joint failure.

Summary: Best Practices for Stainless to Carbon Steel Flange Connections

| Issue | Recommended Solution |

| Welding stainless flange to carbon steel pipe | Use stainless flange + E309 electrode |

| Connecting high alloy equipment to carbon steel pipe | Use a transition spool with matching alloy ends |

| Welding supports to pipe | Use same material for brackets and pipe |

| Bolt tightening in aluminum/stainless piping | Use insulating washers to prevent galvanic corrosion |

Final Thoughts

Joining stainless steel and carbon steel flanges is a technical challenge, especially in high-temperature environments. However, with careful planning—including proper material selection, use of transition pieces, and galvanic isolation techniques—safe and efficient operation can be achieved.

At Haihao Group, we specialize in custom piping system solutions for complex alloy combinations. Whether you’re dealing with stainless-to-carbon transitions, high-temperature flanged joints, or dissimilar metal welds, our engineering team is here to assist.

Contact us today for technical support, custom fabrication, or standard-compliant flange products. Email:sales@haihaogroup.com