Fast-Track Production of ASME B16.5 RF Slip-On Flanges for a Singapore Project

At Haihao Group, we understand that not every piping order follows a predictable schedule. In critical industrial projects, unplanned shutdowns or urgent replacements often require fast production and reliable delivery.

Recently, our team was tasked with an expedited order from a client in Singapore who needed a batch of ASME B16.5 RF Slip-On flanges on very short notice. The project involved maintaining a process pipeline where downtime costs could quickly escalate.

Project Overview and Technical Requirements

Specification Summary:

Flange Type: Raised Face (RF) Slip-On Flange

Standard: ASME B16.5

Material: ASTM A105N (normalized carbon steel)

Size: 2 inch nominal bore

Pressure Rating: Class 150#

Thickness: Standard (STD)

End Details: Serrated concentric finish on the sealing face

Protection: Each flange supplied with a high-quality plastic cap to protect the sealing surface during transport and storage

One detail that mattered to this customer was the serrated finish on the gasket contact area. They required a precise concentric groove finish to achieve consistent sealing performance once installed. We confirmed the surface roughness within their specified range, in line with ASME B16.5 recommendations.

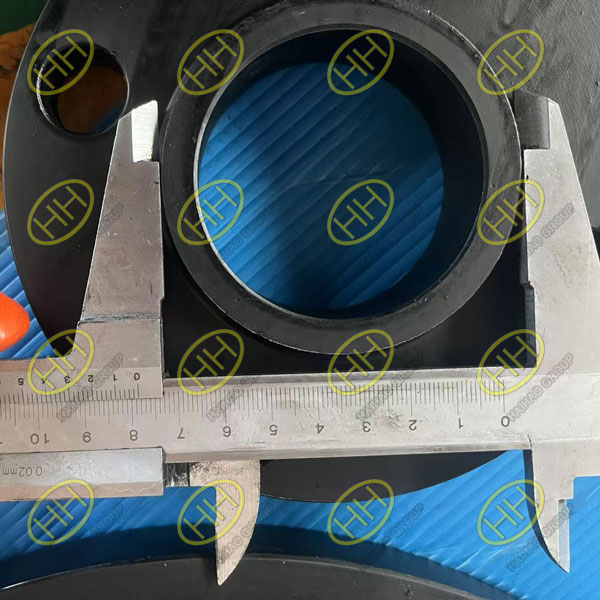

Engineer measuring bolt circle and thickness of 2 inch ASTM A105N slip on flange according to ASME B16.5 standard

How We Managed the Tight Schedule

When the order was confirmed, our production team immediately prioritized the raw material allocation. Because we maintain a steady inventory of A105N forgings in standard sizes, we could bypass the typical waiting time for billet cutting.

Our process included:

- Material verification: PMI and heat certificate review before machining.

- CNC machining: Turning, facing, and drilling completed within two days.

- Dimensional inspection: Each flange checked against ASME B16.5 tolerances for bolt circle, bore diameter, and thickness.

- Serrated face machining: Concentric spiral finish with controlled feed rate to ensure consistent gasket seating.

- Surface protection: Application of anti-corrosion oil on all machined surfaces.

- Plastic flange caps: Installed immediately after final inspection to prevent any damage or contamination.

Within five working days, the full batch was packed in export-grade plywood crates, clearly labeled with heat numbers and inspection details.

Customer Challenges and How We Addressed Them

This client had several pressing concerns:

✅ Downtime Impact: Every day without the flanges meant process interruption. We set up daily production updates to keep their project manager informed.

✅ Sealing Reliability: They needed confirmation that the serrated face was consistent across all units. Our inspection team provided close-up photos and measured profiles for verification before shipping.

✅ Damage Risk: In tropical port environments, packaging is critical. We used shrink-wrapped caps and vapor barrier bags inside the crates to prevent corrosion.

✅ Traceability: All flanges were stamped with heat numbers and included with full EN10204 3.1 certificates.

Final Delivery and Results

The shipment was dispatched by air freight to meet the client’s shutdown window. Upon receipt, their team inspected and installed the flanges without any rework required.

If you have similar situations where urgent delivery is essential, or if you need custom machining and rigorous quality control, our team at Haihao Group is ready to assist.

We combine flexible manufacturing schedules, certified materials, and secure packaging to ensure that even fast-track orders arrive ready to perform.

📧 For inquiries or technical support: sales@haihaogroup.com