-

Enhancing oil production efficiency with orifice flanges A182 F304 ANSI B16.36 from Haihao Group

Haihao Group is proud to have supplied a batch of orifice flanges A182 F304 ANSI B16.36 to a Saudi client’s oil project. Our flanges are known for their exceptional quality, durability, and performance in even the most demanding oil and gas environments. Orifice flanges are a type of pipe ...

-

API and ANSI/ASME flanges: Haihao Group’s high-quality solutions for demanding applications

When it comes to high-pressure and high-temperature applications, API flanges and ANSI/ASME flanges are the go-to solution for many industries. These flanges are designed to withstand extreme conditions, making them ideal for demanding applications such as oil and gas, petrochemicals, and power ...

-

What’s the difference between ANSI/ ASME flanges and API flanges?

ANSI/ASME flanges and API flanges are two types of flanges used in piping systems. ANSI/ASME flanges are designed according to the standards set by the American Society of Mechanical Engineers (ASME). API flanges refer to flanges that comply with the American Petroleum Institute (API) standards. ...

-

ASTM A240 316/316L Paddle Spacer used in Arctic LNG2 Project

The Arctic LNG2 project required the use of high-quality materials that can withstand extreme temperatures and environmental conditions. ASTM A240 316/316L paddle spacer was chosen due to its excellent corrosion resistance, high strength, and robustness. This material is a type of stainless stee ...

-

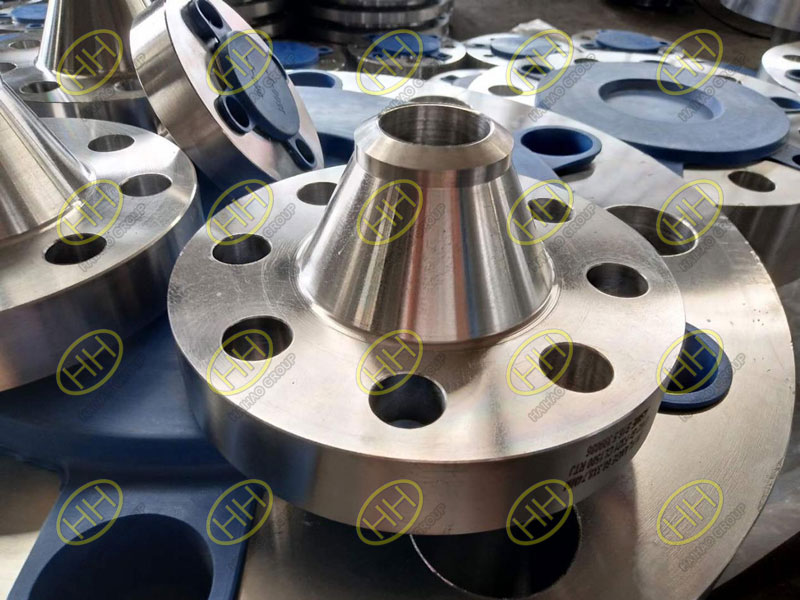

ASTM A350 Gr.LF2 Cl.1 ASME B16.5 C1 weld neck flange applied to Arctic LNG2 project

Haihao Group is a leading manufacturer of high-quality flanges for various industries, including oil and gas, petrochemical, and power generation. Our commitment to excellence is evident in their production of the WN flange used in the Arctic LNG2 project. The 1 inch x 4.5MM PN 63 Series 1 Type ...

-

Quality inspection for ASTM A182 316/316L, ASTM A350 Gr.LF2 weld neck flanegs and blind flanges

The APPLUS VELOSI inspector visited HEBEI HAIHAO HIGH-PRESSURE FLANGE & PIPE FITTINGS GROUP CO., LTD on Jan.13, 2023 to perform final inspection for ASTM A182 316/316L, ASTM A350 Gr.LF2 weld neck flanegs and blind flanges at the end of the article, including visual, dimension, marking, color ...

-

ASTM A182 316/316L, ASTM A350 Gr.LF2 weld neck flanges and blind flanges ready for delivery

Haihao Group recently supplied a range of top-quality flange products. These products include ASTM A350 Gr.LF2 Cl.1 ASME B16.5 weld neck flanges, ASTM A182 316/316L ASME B16.5 RF weld neck flanges, ASTM A350 Gr.LF2 Cl.1 ASME B16.5 RTJ blind flanges, ASTM A182 Gr.F304/304L ASME B16.5 RF blind fla ...

-

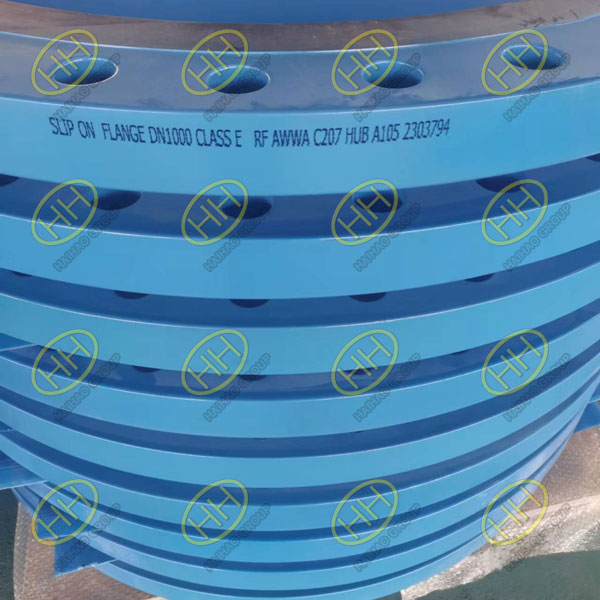

Saudi customer added AWWA C207 A105 slip on flange orders

In mid-March, ASME B16.47A ASTM A105 weld neck flanges and blind flanges ordered by Saudi customers were shipped. The customer expressed great satisfaction with the quality of the products after receiving the goods. Due to the needs of the project, the customer needs to purchase a batch of AWWA ...

-

Characteristics of epoxy powder coatings

As an enterprise dedicated to providing customers with one-stop pipeline engineering products and services, Haihao Group not only has rich pipeline supporting products, but also has the ability to provide customers with coating treatment and engineering solutions. Today, epoxy coating is widely ...

-

Reasons for corrosion of petrochemical pipeline

Due to the sulfur element and acidic substances contained in the pipeline, the corrosion of petrochemical pipeline is also inevitable. Now Haihao shares with you several common causes of petrochemical pipeline corrosion. flanged steel pipe 1.Oxygen absorption corrosion of steel caused by primary ...

-

Bolt type for flange

There are two types of bolts used to connect flanges: single-head bolts and double-head bolts. Their threads are generally triangular metric coarse threads. Let’s take a closer look at these two products. Single-head bolts are also known as hexagon-head bolts. Single-head bolts can be divi ...

-

Types of blind flange

The function of blind flange is to cut off the medium in the pipeline, which can be divided into the following types according to the use pressure and the form of sealing surface: ANSI B16.5 ASTM A182 F304 blind flange 1.Smooth face blind flange is used with smooth sealing face flange, and its a ...