What’s the difference between ANSI/ ASME flanges and API flanges?

ANSI/ASME flanges and API flanges are two types of flanges used in piping systems. ANSI/ASME flanges are designed according to the standards set by the American Society of Mechanical Engineers (ASME). API flanges refer to flanges that comply with the American Petroleum Institute (API) standards.The main differences between these two types of flanges are:

Types of Flanges:

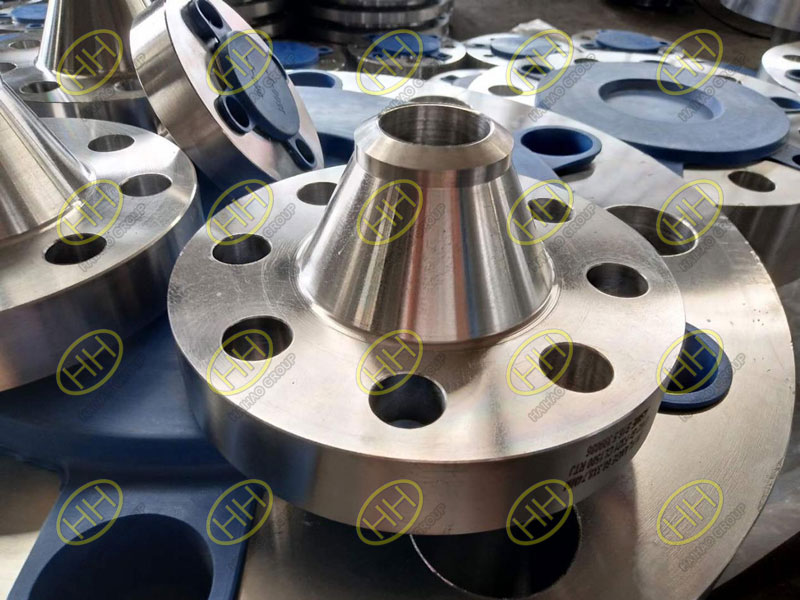

ANSI/ASME flanges are available in different types, including weld neck flanges, slip-on flanges, blind flanges, lap joint flanges, threaded flanges, and socket weld flanges.

API flanges are available in several types: weld neck flanges, slip-on flanges,blind flagnes,socket weld flanges and threaded flanges.

Application Areas:

In terms of application fields, ANSI/ASME flanges are commonly used in the oil and gas, chemical, pharmaceutical, and other process industries. They are typically installed in pipelines for the transportation of fluids, gases, and chemicals. Moreover, these flanges are also used in power plants, water treatment facilities, and other large-scale infrastructure projects.

API flanges are used in a wide range of applications, including oil and gas pipelines, refineries, chemical plants, and offshore platforms. They are known for their reliability, durability, and ability to withstand high pressure and temperature conditions.

Characteristics:

One of the main characteristics of ANSI/ASME flanges is their high level of standardization, which ensures compatibility between different manufacturers and helps to reduce the risk of leakage or other operational issues. Additionally, ANSI/ASME flanges are known for their durability, corrosion resistance, and strength, which makes them suitable for high-pressure and high-temperature applications.

Some of the key characteristics of API flanges include:High strength and corrosion resistance; accurate dimensions for proper alignment and sealing; strict manufacturing standards to ensure quality and safety;compatibility with a wide range of pipes and fittings; availability in a variety of materials, such as carbon steel, stainless steel, and alloy steel.

As a professional manufacturer of forged flange in China,Haihao Group can produce all kinds of ANSI/ASME flanges and API flanges according to customer requirements.We can also provide other standard flanges according to customer requirements. If you have any questions about forged flange products, please feel free to contact us.