Connection method between heat exchanger tubes and tube sheets-Expansion Joint

The connection between tubes and tube sheets is a crucial structural component in the design of shell and tube heat exchangers. This process not only involves significant machining work but also requires that every connection maintains a leak-proof seal and withstands the pressure of the working medium during operation. There are three main structural forms for connecting tubes and tube sheets: expansion joints, welding, and a combination of expansion and welding. In this article, we will first introduce the expansion joint method.

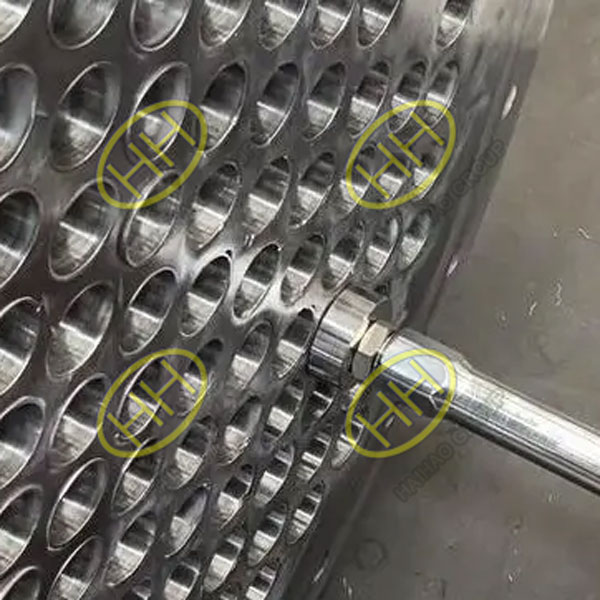

The expansion joint structure is simple and allows for easy tube repair. It is mainly used in situations where medium leakage between the tubes does not result in adverse consequences. During the connection process, an expander is first inserted into the tube, enlarging the tube’s diameter and causing plastic deformation that tightly fits against the tube sheet. As the tube expands, the tube sheet, in contact with the enlarged tube end, also undergoes elastic deformation. When the expander is removed, the tube sheet’s elastic deformation returns to its original size, while the tube’s plastic deformation remains, resulting in a tight connection between the two.

The quality of the expansion joint primarily depends on the radial residual compressive stress at the tube end. This value is influenced by factors such as the materials and dimensions of the tube and tube sheet, whether grooves are present, the expansion rate, the radial clearance between the tube and tube sheet, and surface roughness. To achieve good and stable expansion joint performance, it is essential to strictly control the machining accuracy of the tube sheet, ensure an appropriate hardness difference between the tube and tube sheet materials, correctly select the expander, determine the expansion force, and implement suitable control methods. Additionally, appropriate expansion levels and reasonable expansion sequences must be maintained.

Traditional tube expanding processes include:

Roller Expansion Process

Explosive Expansion Process

Newer tube expanding processes include:

Hydraulic Expansion Process

Rubber Expansion Process

In the following content, we will provide detailed information on various tube expanding processes. As a comprehensive supplier of pipeline system products with over 40 years of experience in the field, Haihao Group is well-versed in various aspects of pipeline systems and has successfully participated in numerous pipeline construction projects. If you would like to learn more, please feel free to contact us.