Introduction to traditional expansion joint techniques for heat exchanger tubes and tube sheets

The traditional expansion joint techniques for connecting heat exchanger tubes to tube sheets include the roller expansion method and the explosive expansion method. Let’s take a closer look at these two methods.

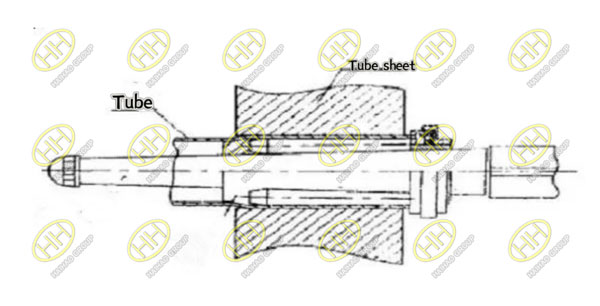

Roller Expansion Method: This technique involves embedding three small-diameter rollers into a frame, along with a conical core shaft of the expander. During the expansion process, the cylindrical section of the expander is inserted into the tube hole. The core shaft is rotated using electric or pneumatic power, causing the rollers to rotate circumferentially around the core shaft. This action forces the core shaft against the inner surface of the tube, effectively expanding the tube to achieve a certain level of tightness, ensuring a secure connection with the tube sheet. The following diagram illustrates this process:

The expansion operation can be divided into two types: advancing and retracting. The advancing method involves inserting the frame into the tube, rotating the core shaft to expand the tube until the desired tightness is achieved. The motor then reverses, withdrawing the expander from the tube to complete the process. In the retracting method, the core shaft is similarly rotated to expand the tube. Once the required tightness is reached, the motor stops, and the clutch of the retracting device engages, allowing the rollers and core shaft to maintain their relative positions while retracting uniformly from the specified depth to the entrance.

This expansion process occurs from the inside out, with the elongation of the tube happening on the outer side of the tube sheet. This helps eliminate the stress state of the tube bundle and improves product quality, making it suitable for connections where the expansion length exceeds 60 cm.

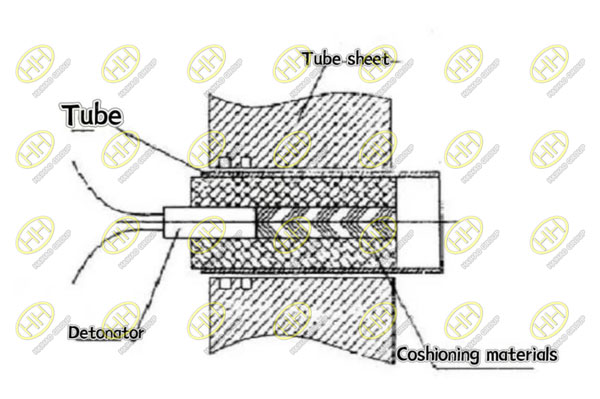

Explosive Expansion Method: This technique employs high-energy explosives to generate a massive pressure wave during the explosion (lasting from 10×10^-6 to 12×10^-6 seconds). The shockwave forces the tube to undergo rapid plastic deformation, effectively expanding it and connecting it to the tube sheet. The schematic diagram of this process is shown below:

In the diagram, the cylindrical explosive is placed at the center of the tube end. To prevent damage to the tube wall from the shockwave, a tubular buffer material (such as a viscous substance or plastic) surrounds the explosive, allowing pressure to be evenly transmitted to the tube wall.

If you would like to learn more about pipeline systems or inquire about our related products, please feel free to contact us.