Method of flange connection

Flange connection consists of a pair of flanges, a gasket and a number of bolts and nuts.

Flanges with holes, can wear bolts, so that the two flanges are tightly connected, between the flanges with gasket sealing. The gasket is placed between the sealing surface of two flanges. After the nut is tightened, the specific pressure on the surface of the gasket reaches a certain value and generates deformation, and fills the uneven place on the sealing surface, so that the connection is tight without leakage. Flanges are threaded connection flanges and welded flanges.

According to the connected parts can be divided into container flange and pipe flange.

According to the structure type, there are integral flanges, threaded flanges, flat welded flanges, looping (loose sleeve, loose tongue) flanges and flange covers.

The integral flange refers to the import and export flange of the pump, valve, machine and other mechanical equipment connected with the pipeline, usually made of these pipeline equipment as a part of the equipment.

The threaded flange is a kind of non-welded flange that processes the inner hole of the flange into a pipe thread and is connected with a pipe with a thread. Compared with the welding flange, it has the characteristics of convenient installation and maintenance, and can be used in some occasions where welding is not allowed on site. However, at temperatures above 260 ° C and below -45 ° C, it is recommended not to use threaded flanges to avoid leakage.

Flat welded flange is also called lap welded flange. The connection between the flat welded flange and the pipe is to insert the pipe into the inner hole of the flange to the appropriate position, and then in the lap welding, its advantage is that the welding assembly is easier to align, and the price is cheap, so it has been widely used. According to the internal pressure calculation, the strength of the flat welded flange is about two-thirds of the corresponding butt welded flange, and the fatigue life is about one-third of the butt welded flange. Therefore, the flat welded flange is only suitable for the pipeline system where the pressure level is relatively low and the pressure fluctuation, vibration and shock are not serious.

Butt welded flange is also known as high neck flange, which is different from other flanges in that there is a long and inclined high neck from the flange and pipe welding to the flange, and the wall thickness of this section of high neck gradually transitions to the wall thickness along the height direction, improving the stress discontinuity, thus increasing the strength of the flange. Butt welded flange is mainly used in harsh working conditions, such as pipe thermal expansion or other loads to make the flange subjected to greater stress, or stress changes repeatedly occasions; Pipelines with large fluctuations in pressure and temperature and pipelines with high temperature, high pressure and sub-zero low temperature.

Butt welding: butt resistance welding (referred to as butt welding) is a kind of resistance welding method that uses resistance heat to weld two workpieces together along the entire end face. Butt welding is widely used because of its high productivity and easy automation.

The flange connection is also the most commonly used connection form of valves in the HVAC industry. According to the shape of the joint surface, it can be divided into the following types:

Smooth: for valves with low pressure. Processing is more convenient.

Concave and convex type: high working pressure, can use a hard washer.

Mortise and groove type: The gasket with large plastic deformation can be used widely in corrosive media, and the sealing effect is better.

Trapezoidal groove type: with oval metal ring as a washer, used in the working pressure ≥64 kg /cm2 of valves, or high temperature valves.

Lens type: The gasket is a lens shape and is made of metal. High pressure valves with working pressure ≥100 kg /cm2, or high temperature valves.

O-ring type: This is a newer form of flange connection, which is developed with the emergence of various rubber O-rings, and it is more reliable than the general flat gasket in sealing effect.

Low pressure small diameter threaded flange, high pressure and low pressure large diameter are used welding flange, flange thickness and the number of connecting bolt diameter and different pressures are different.

Flange connection is an important connection mode in pipeline construction. Flange connection is to put two pipes or equipment, first each fixed on a flange, between the two flanges, flange pad, with bolts fastening together, completed the connection. Some pipe fittings and equipment have flanged, also belong to flange connection. Flange pads are also made of different materials according to the different levels of pressure, ranging from low pressure asbestos pads, high pressure asbestos pads and tetrafluoroethylene pads to metal pads. Flange connection easy to use, can withstand greater pressure. Flange connection is characterized by easy disassembly, high strength, good sealing performance. When installing the flange, it is required that the sealing surface of the two flanges should not be damaged and should be cleaned. Gaskets used for flanges should be selected according to the design regulations.

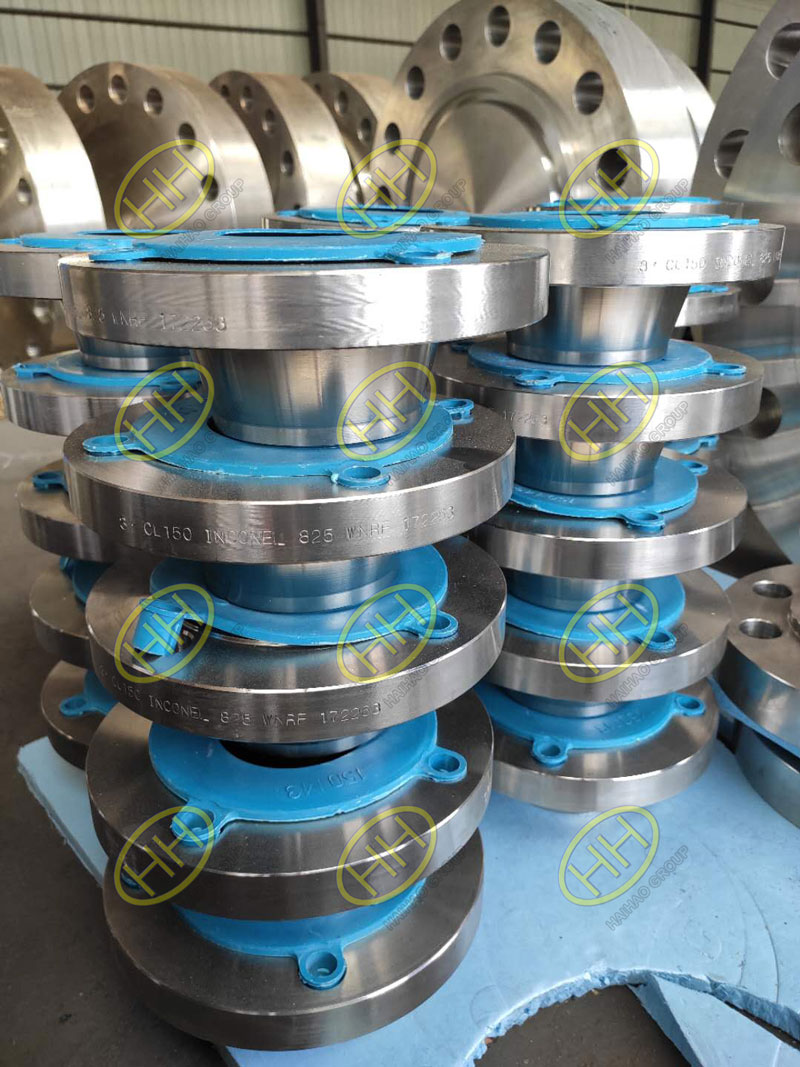

Haihao Group specializes in producing flanged pipe fittings and other products, and is very skilled in flange connection. Undertake a lot of domestic and foreign large-scale project flange pipe fittings supply, welcome interested new and old customers to inquire.Email:sales@haihaogroup.com