Haihao Group Strengthens Presence in the Middle East with Customized A105N Flange Solutions

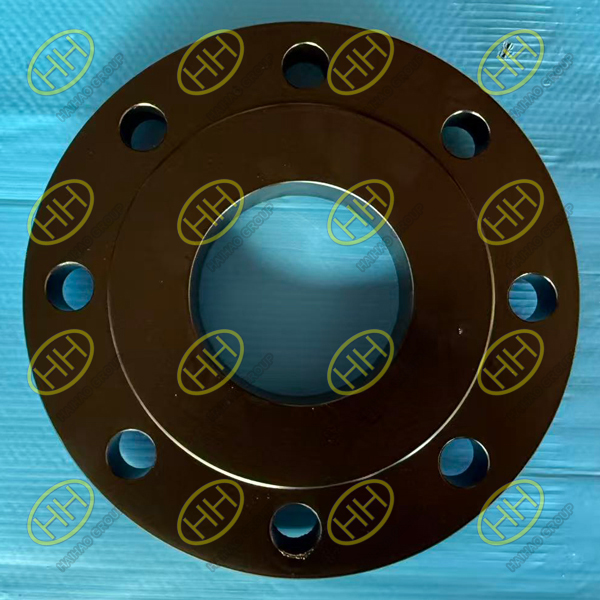

Haihao Group has once again demonstrated its technical expertise by completing a customized production of A105N carbon steel flanges for a major energy infrastructure project in Dubai.

This project underscores the company’s capability to provide precision-engineered pipeline components that meet the highest international standards, including ASME B16.5, ASME B16.47, and NACE MR0103.

Unlike standard flange production, this order required bespoke designs based on the client’s drawings, strict mechanical property requirements, and enhanced corrosion protection — a challenge that Haihao engineers turned into an opportunity to display their advanced manufacturing know-how.

Innovative Manufacturing and Rigorous Quality Control

At Haihao Group’s advanced production base, each A105N weld neck, blind, and jacketed flange underwent CNC machining, heat treatment, and dimensional calibration to ensure perfect fit and durability.

The 36-inch ASME B16.47 Series A weld neck flanges were specially normalized and tested for sour service in full compliance with NACE MR0103, ensuring performance reliability even in aggressive service conditions common in the Middle East’s petrochemical and refinery sectors.

To guarantee excellence, every flange passed non-destructive testing (NDT) and mechanical verification before packaging — reflecting Haihao’s commitment to zero-defect delivery.

Custom Jacketed Flanges: Designed for Process Efficiency

One of the highlights of this project is the production of custom jacketed flanges, which are used in systems that require precise temperature control for the transportation of viscous or heat-sensitive fluids.

Haihao engineers optimized the jacket welding configuration and heat dissipation design to improve thermal uniformity, ensuring seamless integration with the client’s existing pipeline systems.

This advanced fabrication process not only enhances process efficiency but also extends the service life of the entire piping network.

Commitment to Global Projects and Long-Term Partnerships

Haihao Group’s success in this Dubai project is part of its broader strategy to support global EPC contractors, refineries, and energy companies with high-quality piping components.

With decades of experience as a leading Chinese flange manufacturer and exporter, Haihao continues to deliver custom-engineered carbon steel flanges and stainless steel fittings to clients in the Middle East, Europe, and Southeast Asia.

The company’s integrated production, from raw material forging to precision machining and testing, ensures consistent quality and timely delivery for every project.