Haihao Group delivers robust ASME B16.5 A350 LF2 weld neck flanges to Indonesian client

In the intricate world of industrial pipelines, the integrity of every connection is paramount for operational safety and efficiency. Flanges serve as crucial connecting points, ensuring leak-proof seals and structural stability under immense pressure and varying temperatures. Haihao Group, a globally trusted manufacturer of pipe fittings and flanges, is pleased to announce a significant delivery of specialized ASME B16.5 A350 LF2 RF Weld Neck Flanges to a key client in Indonesia.This recent project highlights Haihao Group’s continued dedication to supporting industrial growth in Indonesia and across the Asia-Pacific region.

Product Spotlight: ASME B16.5 A350 LF2 RF Weld Neck Flanges

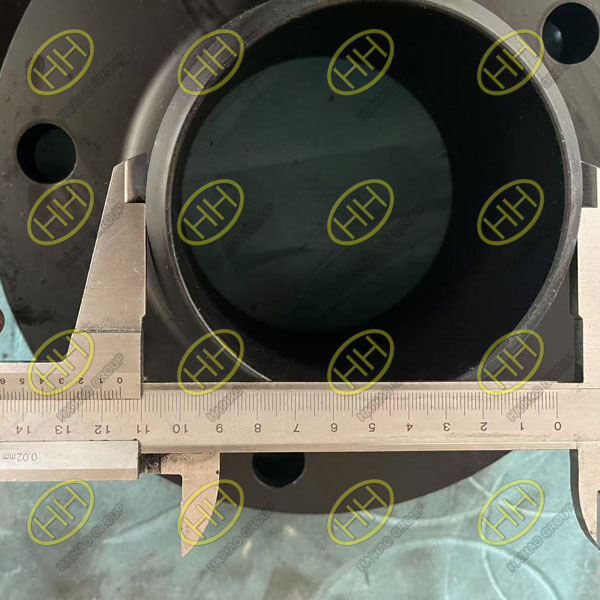

The core of this significant order consisted of weld neck flanges forged from ASTM A350 Grade LF2 carbon steel, all manufactured to ASME B16.5 standard, featuring a Raised Face (RF), and finished with a protective black paint coating.

- Material: ASTM A350 Grade LF2 (Low Temperature Carbon Steel)

- Type: Weld Neck Flange (WN)

- Facing: Raised Face (RF)

- Standard: ASME B16.5

- Coating: Black Painted (Anti-Corrosion Treatment)

- End Connection: Butt Weld (BW)

- Application: Low-temperature and pressure piping systems including oil, gas, and chemical industries.

Supplied Product Specifications

| Item No. | Standard | Material | Size (Inch) | Class (lb) | Facing | Wall Thickness (mm) | Type | Coating |

|---|---|---|---|---|---|---|---|---|

| 1 | ASME B16.5 | A350 LF2 | 6″ | 150# | RF | 10.97 | Weld Neck | Black Painted |

| 2 | 4″ | 6.02 | ||||||

| 3 | 6″ | 21.95 |

Project Background: Tailored Solution for Indonesian Customer

For this shipment to Indonesia, Haihao Group customized the flanges with a black painting surface treatment, as per the client’s specific storage and environmental protection requirements. The black paint prevents rust and mechanical damage during transit and field storage, ensuring the flanges arrive in perfect condition for welding and installation.

A350 LF2 weld neck flanges are especially suited for low-temperature service, providing excellent performance in oil & gas pipelines and petrochemical plants where both strength and ductility at sub-zero temperatures are required.

The Haihao Group Difference: Uncompromising Quality and Global Service

Haihao Group’s reputation as a top-tier manufacturer is built on:

Manufacturing Prowess: Leveraging advanced forging and machining capabilities to produce flanges with exceptional precision and structural integrity.

Rigorous Quality Control: Implementing comprehensive testing and inspection protocols, from raw material verification to final product checks, ensuring every flange meets stringent quality benchmarks.

Customer-Centric Solutions: Our team excels in understanding specific project requirements and delivering tailored solutions, including specialized materials and protective coatings.

Efficient Global Logistics: Our robust supply chain ensures timely and secure delivery of complex orders to clients across the globe, including dynamic markets like Indonesia.

Contact Haihao Group today to discuss your flange and piping component requirements, and discover how our dedication to quality and service can contribute to your project’s success.