Differences between flat welding flange and butt welding flange

In the world of industrial piping, selecting the correct flange type is paramount for system integrity and operational safety. Two of the most commonly encountered flange types are the flat welding flange (often known as a slip-on flange) and the butt welding flange (also called a weld neck flange). While both serve to connect pipes and components, their distinct designs dictate their optimal applications and performance characteristics.

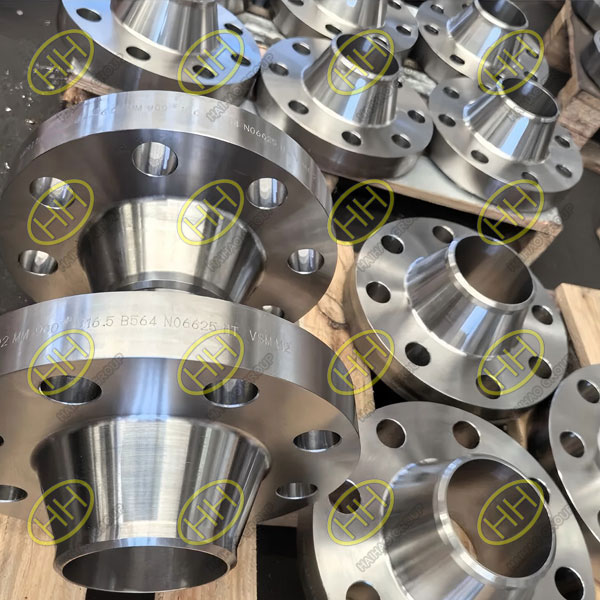

At Haihao Group, our engineers frequently advise clients on these critical distinctions. Understanding the fundamental differences is key to making informed decisions for your project.

Understanding the Fundamentals: flat welding flange vs. butt welding flange

Flat Welding Flange (Slip-On)

- Pipe slides into the flange bore.

- Secured with two fillet welds—inside and outside.

- Easy alignment and installation.

Butt Welding Flange (Weld Neck)

- Long tapered neck, designed for butt weld.

- Ensures smooth stress transition from flange to pipe.

- Superior strength for high-pressure and high-temperature uses.

Technical Comparison Table

| Feature | Flat Welding Flange (Slip-On) | Butt Welding Flange (Weld Neck) |

|---|---|---|

| Weld Type | Double Fillet Weld | Full-Penetration Butt Weld |

| Pressure Capacity | Low to Medium | High |

| Installation Ease | Simple, less skill needed | Skilled welder required, precise fit-up |

| Typical Use | Cooling water, fire protection | Oil & gas, steam lines, refineries |

| Fatigue Resistance | Lower | Excellent |

In a recent oil refinery project in Singapore, Haihao Group supplied weld neck flanges that passed hydro testing at 10 MPa and ultrasonic testing with 100% coverage—ensuring zero internal defects. The client reported zero leak failures after one year of service.

FAQs

Q1: Which flange is better for high-pressure pipelines?

A1: Butt Welding (Weld Neck) flanges provide superior integrity and are best for high-pressure, high-temperature systems.

Q2: Is Slip-On flange suitable for gas service?

A2: Generally not recommended for gas or critical fluid systems due to potential fatigue and leakage risks. Weld Neck is preferred.

Q3: Can Haihao Group supply flanges with ASME B16.5 certification?

A3: Yes, all flanges meet ASME B16.5, EN1092-1 or client-specific standards, with full material traceability.

For cost-effective, low-pressure use, flat welding flanges are ideal. For demanding, high-stress environments, butt welding flanges provide unmatched safety and longevity. Understand the critical differences between flat welding (slip-on) and butt welding (weld neck) flanges. Haihao Group provides expert insights on design, performance, installation, and application to help you choose the right solution. Email:sales@haihaogroup.com