-

Haihao Group Ships ASME B16.5 A105N Carbon Steel Flanges to Singapore Client

Haihao Group recently completed the manufacturing and shipment of a full range of ASME B16.5 A105N carbon steel flanges for a customer based in Singapore. The shipment included a variety of flange types—slip on (SO RF), weld neck (WN RF), and blind (BL RF)—covering pressure ratings of 150# and 3 ...

-

Delivery of super-duplex paddle blanks, spacers & figure 8 blanks to Singapore

Over the past month, Haihao Group completed a specialized shipment of RTJ paddle blank flanges, paddle spacers, and figure 8 blanks for a major Singapore process-plant project. Our team delivered seven unique items—ranging from 2-inch inserts to 12-inch blanks—each engineered to handle pressures ...

-

Haihao Group delivers custom-made ASME B16.5 flanges to German client, supporting Europe’s high-precision piping needs

Germany, as one of Europe’s most advanced manufacturing hubs, is renowned for its rigorous standards in engineering and industrial systems. For suppliers in the piping component industry, delivering high-quality, standard-compliant, and customized products is the key to earning trust in su ...

-

Haihao Group Delivers GOST 33259 WN Flanges and High-Performance Fasteners for Global Client

In today’s industrial landscape, the reliability of pipeline connections is paramount—especially in critical systems operating under high temperature and pressure. Haihao Group, a leading global supplier of pipe fittings, flanges, and gasket solutions, has once again demonstrated its manuf ...

-

How to Properly Connect Stainless Steel Flanges to Carbon Steel Flanges at High Temperatures

In industrial piping systems, it is generally recommended to avoid mixing different metals—especially stainless steel and carbon steel—due to the risk of galvanic corrosion, thermal stress mismatch, and mechanical incompatibility. However, in many practical scenarios, especially in petrochemical ...

-

Fast-Track Production of ASME B16.5 RF Slip-On Flanges for a Singapore Project

At Haihao Group, we understand that not every piping order follows a predictable schedule. In critical industrial projects, unplanned shutdowns or urgent replacements often require fast production and reliable delivery. Recently, our team was tasked with an expedited order from a client in Singa ...

-

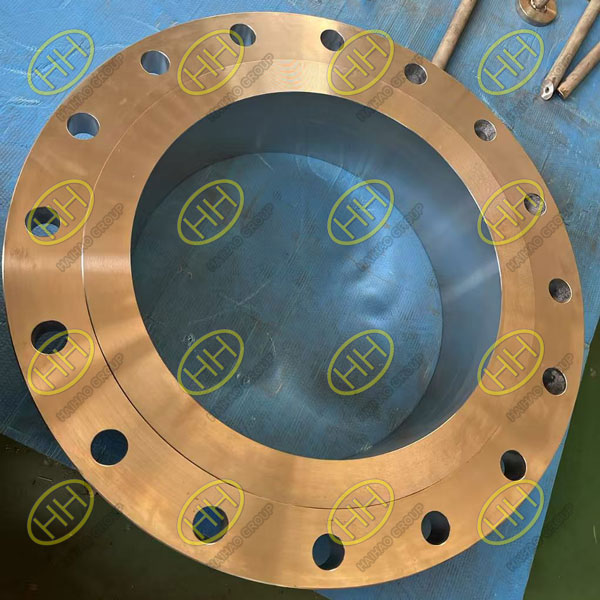

Haihao Group delivers S235JR2 custom flanges to Danish client

In demanding industrial environments, the longevity and reliable performance of pipeline components are paramount. While every connection must be robust, specific applications call for enhanced protection and meticulous precision. At Haihao Group, we recently completed a detailed order for a val ...

-

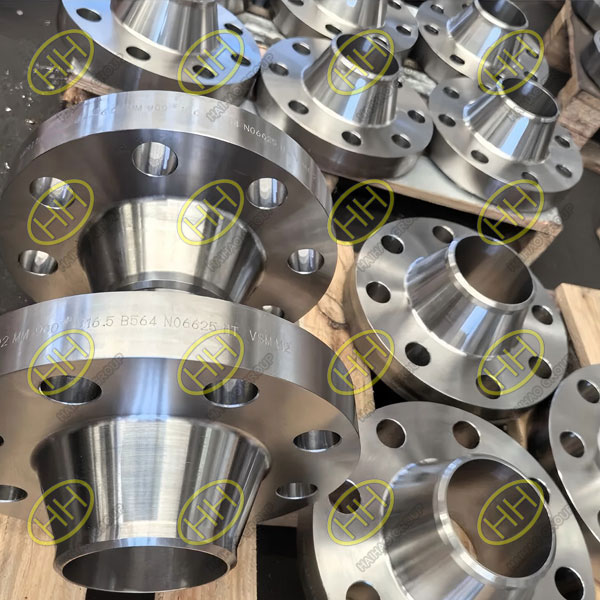

ASME B16.5 A182 Gr.F316L Weld Neck Flanges Custom-Bored for Russian Project

A few days ago, we wrapped up a small but very specific job for a client in Russia—16-inch weld neck flanges, made from ASTM A182 F316L stainless steel, with some non-standard requirements that needed a bit more attention than usual. The client is working on a pipeline section that uses 406.4 mm ...

-

Haihao Group delivers robust ASME B16.5 A350 LF2 weld neck flanges to Indonesian client

In the intricate world of industrial pipelines, the integrity of every connection is paramount for operational safety and efficiency. Flanges serve as crucial connecting points, ensuring leak-proof seals and structural stability under immense pressure and varying temperatures. Haihao Group, a gl ...

-

What is the ASME standard for flanges?

In the world of piping and pressure vessel systems, ASME flange standards play a critical role in ensuring safety, reliability, and global compatibility. Whether used in oil & gas, chemical processing, power generation, or water treatment, flanges serve as essential components for connecting ...

-

What is the difference between ASME B16.36 and ASME B16.5 flanges?

Recently, Haihao Group produced a batch of ASME B16.36 orifice flanges for Singapore customers. In industrial piping systems, choosing the right flange type is crucial for system performance, safety and flow measurement accuracy. The most common one is the ASME B16.5 flange, which is widely used ...

-

ASTM A240 GR.316/316L Spectacle Blinds: Material Properties, Standards, and Applications

In industrial pipeline systems, spectacle blinds play a vital role in system isolation for maintenance, testing, or safety shutdowns. When manufactured from ASTM A240 Grade 316/316L stainless steel, these components offer excellent corrosion resistance, mechanical durability, and compatibility w ...