The purpose and procedure of the red lead test for octagonal gaskets and high-pressure flanges

The red lead test is primarily conducted to assess the contact quality between octagonal gaskets and the sealing surfaces of high-pressure flanges. This straightforward yet effective test ensures optimal sealing performance by identifying irregularities in the contact area.

Testing Procedure

1.Preparation of the Flange Surface:

Clean the flange sealing surface thoroughly to remove any dirt or grease. Apply a uniform layer of paste-like red lead oxide onto the flange surface.

Note: The layer thickness is critical; applying the paste too thinly or too thickly may compromise the test’s accuracy. If results are unsatisfactory, wipe the surface clean with a soft cloth and reapply.

2.Placing the Gasket:

Gently position the octagonal gasket onto the flange’s sealing surface. Once placed, apply pressure and manually rotate the gasket 90°.

For large-diameter flanges (e.g., DN500 and above), teamwork is often required to rotate the gasket. Ensure the pressure applied is consistent across all participants.

3.Inspection:

After rotating the gasket, remove it and inspect the sealing lines on both the flange surface and the gasket.

Continuous sealing lines on the inner and outer edges indicate good contact, which translates to a better sealing performance after installation.

If the sealing lines are discontinuous or inconsistent, replace the gasket with another of the same type and repeat the test until the sealing lines are satisfactory.

Significance

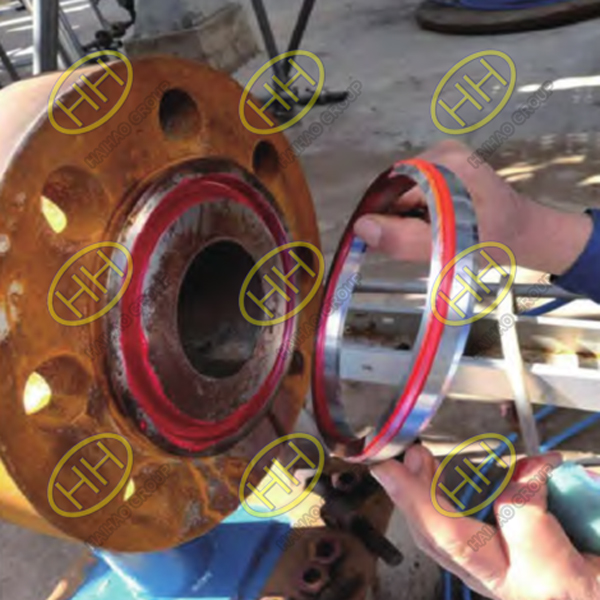

A continuous and uniform sealing line demonstrates excellent contact between the flange and the gasket, as shown in the following figure.This ensures a tight seal under high-pressure conditions, minimizing the risk of leakage. Discontinuous sealing lines indicate the need for adjustments or gasket replacement to achieve the required sealing performance.

The red lead test is an essential step in ensuring the reliability of high-pressure flange connections. By carefully evaluating the contact quality through visual inspection of the sealing lines, engineers can achieve superior sealing efficiency and ensure the safety and durability of pipeline systems.