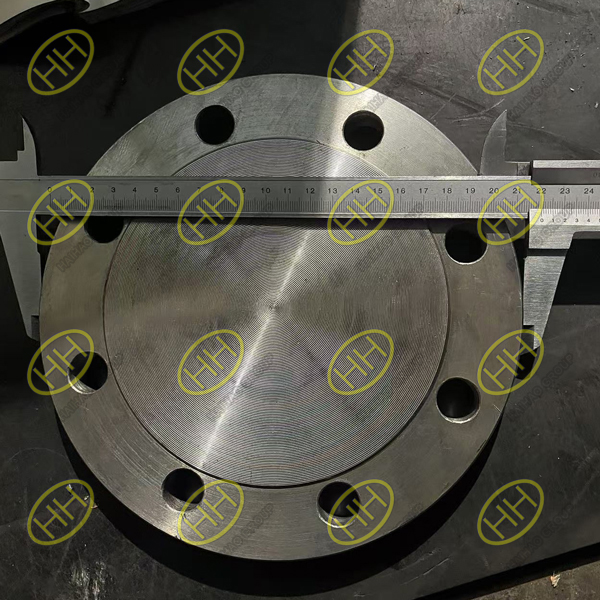

Strict quality inspection of S235JR DIN flanges

At Haihao Group, we prioritize the highest standards of quality control to ensure that our clients receive products that meet their exact specifications and requirements. Recently, we completed a rigorous quality inspection for a batch of flanges ordered by a valued client. The order included DIN standard flanges in S235JR material with various sizes, ranging from DN15 to DN100.

Detailed Quality Inspection Process

Before shipment, our team performed comprehensive inspections on the flanges to verify that they met the required specifications and standards. This inspection process is crucial for ensuring the accuracy and reliability of the products, and includes the following key parameters:

Flange Diameter (OD): We carefully measured the outer diameter of each flange to ensure they matched the specifications provided by the customer. Any deviation in size can affect the overall installation and performance of the piping system, which is why this measurement is essential.

Flange Bore Diameter (ID): The internal diameter of the flanges was checked to verify that it met the required specifications. The bore must be accurate to ensure proper alignment and fit when the flanges are installed in the pipeline.

Seal Face Dimensions: We meticulously measured the sealing faces of the flanges to ensure that they were within the tolerances required by the customer and the relevant industry standards. The correct sealing face dimensions are critical for ensuring a tight, leak-free seal when the flanges are connected.

Overall Dimensions and Tolerances: Our team also conducted detailed checks on the overall dimensions of each flange, including thickness, to ensure that they conformed to the DIN 2527 standard and the specific requirements set by the customer. This is to ensure proper compatibility with other components in the pipeline system.

Customer Notification and Approval

Once the inspections were completed, the results were carefully documented, and the inspection report was shared with our client. We ensured that the customer was fully informed about the inspection results and that all specifications were met. The customer reviewed the results and confirmed their satisfaction with the quality and accuracy of the products.

Shipment and Delivery

After receiving approval from the customer, we proceeded with the shipment of the flanges. The products were securely packaged to prevent any damage during transportation, and they were dispatched to the customer’s location without delay.

At Haihao Group, we take great pride in our commitment to quality and customer satisfaction. This thorough quality inspection process ensures that every batch of flanges, whether for domestic or international clients, meets the highest standards of performance and reliability. We are dedicated to providing exceptional products and services to support the success of our clients’ projects.

If you have any questions or would like to learn more about our products, please don’t hesitate to contact us. We look forward to working with you!