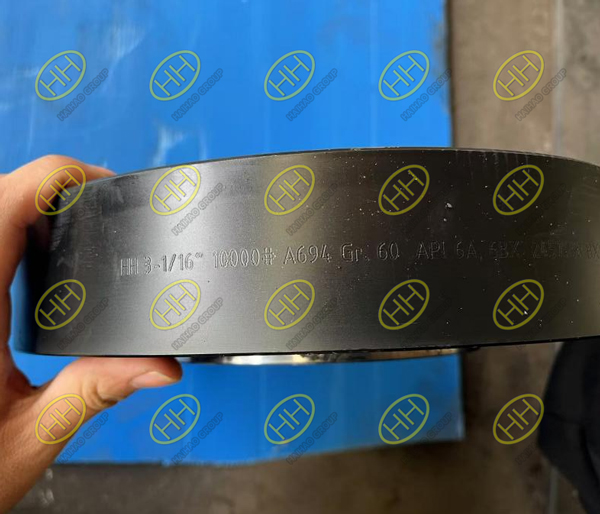

Strict quality requirements meet for API 6A RTJ A694 Gr. 60 PSL3 blind flange

Haihao Group recently completed production of a batch of API 6A RTJ A694 Gr. 60 PSL3 blind flanges for a distinguished client in the UAE. The order came with stringent quality requirements, demonstrating the client’s commitment to safety and performance in critical applications. Haihao Group successfully met all the specifications, highlighting our expertise and commitment to excellence in manufacturing pipeline components.

Client’s Stringent Quality Requirements

Low Sulfur Content (S ≤ 0.01%)

The sulfur content in the material was strictly controlled to ensure superior resistance to corrosion and mechanical integrity under extreme operating conditions.

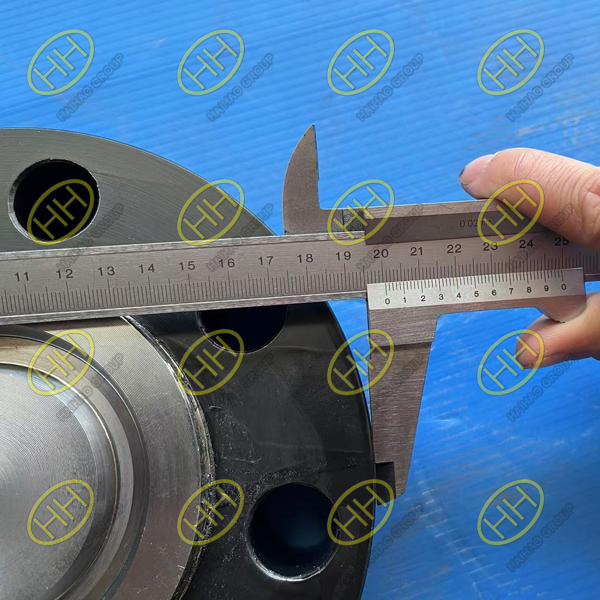

Comprehensive Ultrasonic Testing (UT)

Before Machining: UT inspection was performed on raw materials to detect any internal defects that could compromise the flange’s structural integrity.

Post-Machining: Final UT inspection ensured that the finished flanges were free from cracks, voids, or other imperfections, meeting the client’s strict quality standards.

Carbon Equivalent (CE ≤ 0.43)

The maximum carbon equivalent was carefully monitored and controlled to ensure weldability and minimize the risk of cracking during fabrication or operation.

Low-Temperature Charpy Impact at -46°C

The flanges were rigorously tested to demonstrate excellent toughness and impact resistance at -46°C, ensuring reliable performance in low-temperature applications.

Haihao Group’s Expertise in Meeting the Requirements

Material Selection: We sourced and utilized high-grade A694 Gr. 60 material to meet the chemical composition and mechanical property requirements.

Advanced Testing Capabilities: Our state-of-the-art testing facilities and skilled quality control team ensured that all products passed the required UT, chemical composition, and mechanical property tests.

Low-Temperature Expertise: With years of experience producing components for low-temperature environments, Haihao Group ensured that the products met the -46°C impact testing requirements.

Demonstrating Haihao Group’s Strength

This project showcases Haihao Group’s ability to meet the most demanding requirements in the oil and gas industry. In addition to the API 6A PSL3 blind flanges, our company holds extensive certifications and expertise in producing high-quality components, including:

Material grades suitable for extreme environments.

Compliance with multiple international standards and third-party inspections.

Our proven track record positions Haihao Group as a trusted partner for clients worldwide, capable of delivering products that meet or exceed the most stringent requirements.

The API 6A RTJ A694 Gr. 60 PSL3 blind flanges manufactured for the UAE client demonstrate Haihao Group’s unwavering commitment to quality and excellence. By meeting stringent requirements for sulfur content, UT inspection, carbon equivalent, and low-temperature toughness, we continue to reinforce our position as a leader in the global pipeline component industry.