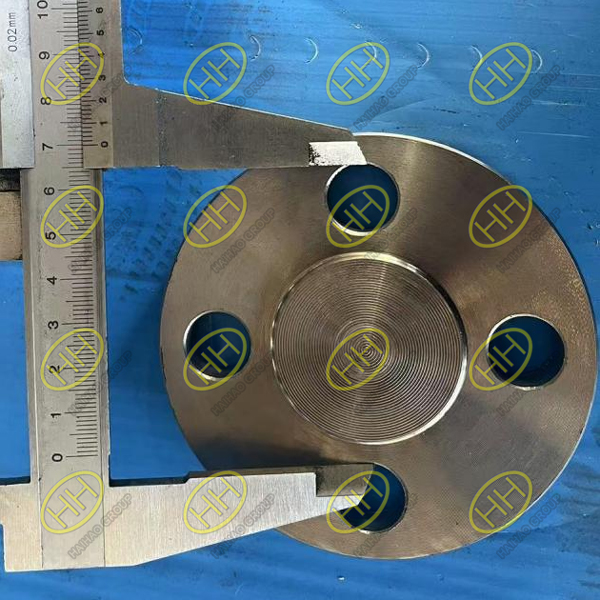

Quality inspection of ASME B16.5 A350 GR.LF2CL.1 blind flange

At Haihao Group, quality assurance is paramount. Recently, we conducted a comprehensive dimensional inspection of a batch of ASME B16.5 RF A350 GR.LF2CL.1 blind flanges, ensuring they met both international standards and our client’s specifications. Dimensional inspection plays a critical role in guaranteeing the reliability and safety of flanges used in piping systems.

Key Aspects of Flange Dimensional Inspection

Dimensional inspection ensures that flanges are manufactured to precise specifications, allowing seamless integration into piping systems. Below are the primary aspects inspected:

1.Outer and Inner Diameter

Outer Diameter (OD): Verifies the overall size of the flange to ensure compatibility with adjoining components.

Inner Diameter (ID): Ensures the bore of the flange matches the connected pipe size, avoiding misalignment.

2.Bolt Hole Size and Alignment

Bolt Hole Diameter: Confirmed to accommodate specified bolt sizes for secure connections.

Bolt Hole Circle Diameter (BC): The center-to-center distance of bolt holes must align perfectly for easy assembly.

Bolt Hole Number and Placement: Ensures the exact number of bolt holes and their symmetrical positioning to prevent assembly issues.

3.Raised Face (RF) Dimensions

For raised face flanges, the height and diameter of the raised face are measured to ensure proper gasket seating and effective sealing.

4.Thickness

Flange Thickness: Validates the flange’s ability to withstand the rated pressure without deformation or failure.

5.Flatness and Surface Finish

Flatness: Checked to ensure the flange lies perfectly flat, critical for achieving a leak-proof seal.

Surface Finish: The gasket contact surface is inspected for smoothness and uniformity to prevent gasket damage and ensure sealing efficiency.

6.Overall Visual Inspection

Surface Quality: Free from cracks, dents, or other defects that could compromise performance.

Markings: Verifies correct stamping of material grade, pressure class, size, and standard compliance.

Why Dimensional Accuracy Matters

Dimensional accuracy ensures:

Seamless Integration: Proper fitment with other piping components.

Structural Integrity: Maintains system safety under pressure and temperature conditions.

Compliance: Adherence to ASME B16.5 or other relevant standards for international compatibility.

Haihao Group’s Commitment to Quality

At Haihao Group, we follow a rigorous quality control process to ensure all flanges meet the highest standards. Using advanced inspection tools and techniques, our experienced team meticulously examines every aspect of flange dimensions. This meticulous approach guarantees that our products perform reliably, even in the most demanding environments.

For more information about our products or quality assurance processes, feel free to contact Haihao Group. Email:sales@haihaogroup.com