Key features and applications of API 6A TYPE 6BX flanges and blind flanges

In high-pressure oil and gas operations, reliable and robust connections are critical for maintaining system integrity and ensuring safety. API 6A TYPE 6BX flanges and blind flanges are essential components designed specifically to meet the stringent demands of such environments. This article highlights the key features and applications of these high-performance components.

1.Exceptional High-Pressure Capability

API 6A TYPE 6BX flanges and blind flanges are engineered to withstand extreme pressures of up to 20,000 psi (1379 bar). This makes them indispensable in high-pressure and ultra-high-pressure applications commonly encountered in the oil and gas industry. Their robust design ensures that they can maintain structural integrity and prevent leaks, even under the most demanding operating conditions.

2.Forged for Strength and Durability

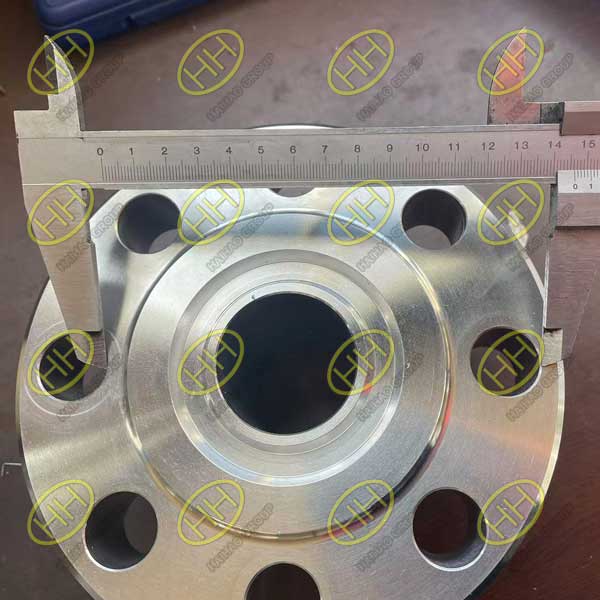

To meet the requirements of the API 6A standard, these flanges and blind flanges are manufactured using high-pressure forging processes. Forging enhances the material’s grain structure, resulting in superior strength, durability, and resistance to fatigue. This ensures that the components perform reliably in high-pressure environments, such as deep-sea drilling or high-temperature operations, where failure is not an option.

3.Strict Quality and Material Standards

The API 6A standard enforces rigorous requirements for materials, dimensions, strength, and overall quality to ensure these flanges and blind flanges can handle challenging conditions. Key aspects of quality control include:

Material Selection: High-strength alloys like ASTM A182 F55 (super duplex stainless steel) or low-alloy steel are commonly used to provide corrosion resistance and toughness.

Dimensional Accuracy: Precision machining ensures compatibility with other API 6A components and a leak-proof fit.

Non-Destructive Testing (NDT): Methods such as ultrasonic testing and radiographic inspection verify the integrity of the components.

These measures guarantee that the flanges and blind flanges meet the highest industry standards for performance and safety.

4.Wide-Ranging Applications

API 6A TYPE 6BX flanges and blind flanges are extensively used in high-pressure oil and gas operations, including:

Oil Wells and Christmas Trees: These components are crucial for connecting high-pressure equipment in oil wellhead assemblies.

Oil and Gas Separators: They provide reliable sealing and connection for separators used in processing crude oil and natural gas.

Flow Meters and Pressure Vessels: Flanges and blind flanges ensure secure, leak-proof connections in systems requiring precise pressure and flow measurement.

High-Pressure Pipelines: They are widely used in the transportation and processing of oil and gas, providing durability and safety in corrosive environments.

The robust sealing performance of TYPE 6BX flanges, combined with their ability to handle extreme pressures, makes them indispensable in maintaining system reliability and efficiency.

The API 6A TYPE 6BX flanges and blind flanges exemplify the highest standards of engineering and manufacturing in the oil and gas industry. With their exceptional high-pressure capabilities, forged durability, strict adherence to quality standards, and versatility in critical applications, these components are indispensable in ensuring the safety and efficiency of high-pressure systems.

Haihao Group is proud to supply API 6A TYPE 6BX flanges and blind flanges that meet the rigorous demands of customers worldwide. Through advanced manufacturing processes and strict quality control, we ensure that every product is built to perform and exceed expectations in even the most challenging environments. Email:sales@haihaogroup.com