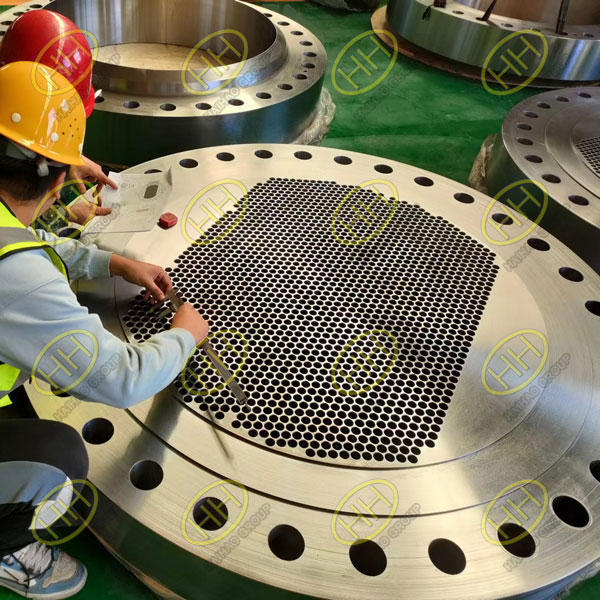

Introduction to new expansion techniques for heat exchanger tubes and tube sheets

The new expansion techniques for connecting heat exchanger tubes to tube sheets include hydraulic expansion and rubber expansion methods. Below, we will provide a detailed introduction to these two techniques.

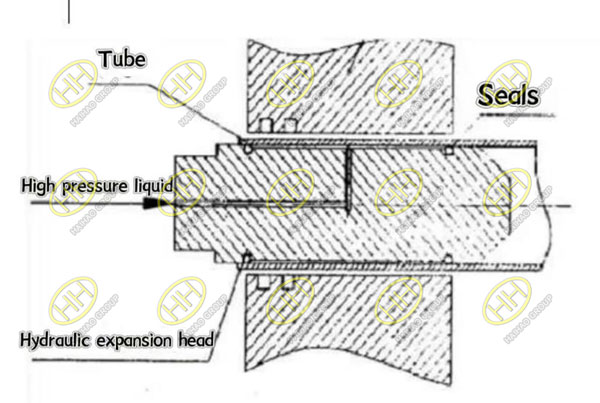

Hydraulic Expansion Method: This technique involves applying high liquid pressure to the inner surface of the tube, causing plastic deformation that expands the tube to fit the surface of the tube sheet. The hydraulic expander consists of a core rod that has a diameter slightly smaller than the inner diameter of the tube. The outer surfaces at both ends of the core rod are equipped with multiple sealing elements, and there is an oil inlet hole in the middle of the core rod. High pressure is applied to the segment between the two sealing elements, resulting in the plastic expansion of the tube and achieving the connection. The schematic diagram is shown below:

Hydraulic expansion offers significant advantages over mechanical expansion, especially for connections where sealing performance is the primary requirement. This method not only enhances work efficiency but also improves the quality of the expansion joint significantly. During operation in power plants, it helps prevent or reduce tube end leaks, thereby minimizing economic losses caused by downtime, resulting in substantial social benefits.

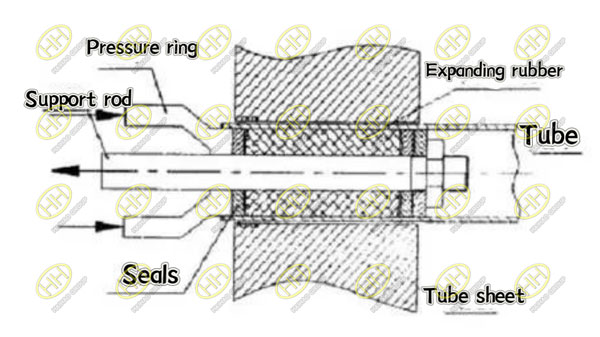

Rubber Expansion Method: The rubber expansion technique is developed based on the deformation of rubber under stress. It utilizes the radial pressure generated by the axial compression of the rubber elastomer to expand the tube into the tube sheet. When the tension rod applies a pulling force, the expansion rubber undergoes axial compression, simultaneously generating radial expansion. This expansion force is sufficient to deform the tube material, achieving the connection between the tube and the tube sheet. The schematic diagram is shown below:

The expansion rubber is made from high-strength, highly elastic materials. To prevent axial movement of the rubber under high pressure, special hard rubber sealing rings are installed at both ends of the expander. The tension rod for the rubber expansion is made from high-strength steel. It is loaded with approximately 20 MPa of pressurized water or oil, and since the pulling force balances against the pressure ring, it forms an internal force system without requiring additional supports or constraints.

If you would like to learn more about pipeline systems or if your engineering project requires supporting products for pipeline systems, please feel free to contact us.Email:sales@haihaogroup.com