What is the difference between forged flanges and cast flanges?

Flanges can either be forged or cast. Both manufacturing methods have their advantages and disadvantages, depending on the application you have in mind for your flange. Haihao Group primarily deal with forged flanges due to the outdated nature and lower standard of quality of cast flanges. Below, we will delve into the advantages and disadvantages of both forged steel flanges and cast flanges.

CAST IRON FLANGES

Casting is the process in which the metal is heated until molten then poured into a mold or vessel to create the desired shape. They are often used in cases that are too large, complicated, or other wise not suitable for forgings. Some of the advantages of flanges manufactured in this way include lower costs of production, the ability to make more intricate parts at lower costs, as well as having no true upper limit on size when it comes to your part.

There are, however, some drawbacks to cast iron flanges. The most important of these being how susceptible they are to internal defects. Due to this, cast flanges are not suitable for high pressure applications or applications in which the probability of corrosion is high. Despite advancement of casting technology and computer optimization of the casting process and designs, it is still difficult to meet the standards required for petrochemical industry applications.

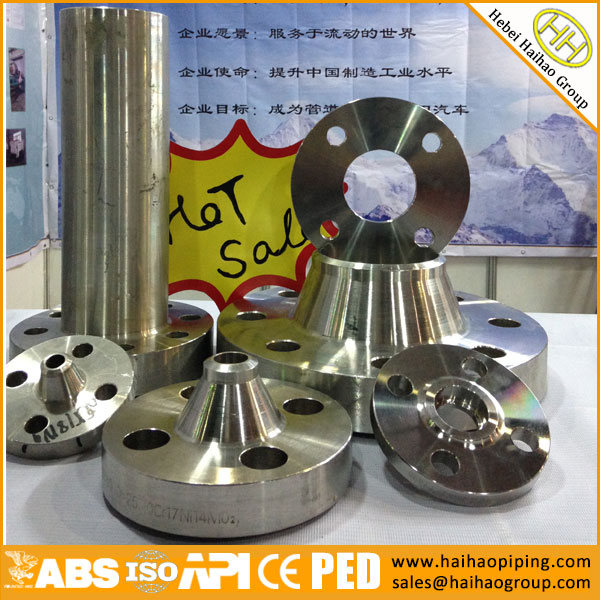

FORGED STEEL FLANGES

Forging is the application of mechanical and thermal energy to steel billets or ingots to cause material to change its shape while still in solid form. Forgings offer consistency in composition and structure. Due to the nature of the production of forged flanges, the production costs are higher than that of cast flanges. Though they cannot have the complex shapes that cast flanges can be made in, their internal structure is more compact and therefore seldom have the defects the often affect cast flanges. Forging eliminates defects found in casting such as shrinkage, porosity, cavities, or cold pour issues.

Generally, forged flanges are stronger and more reliable than cast flanges because the grain flows of the steel are altered, confirming to the shape of the part. The tight grain structure of forgings makes the pieces mechanically stronger, and more resistant to general wear and tear than cast flanges. The higher quality, reliability, strength, and durability are why we deal mostly in forged flanges rather than cast flanges.

Here at Haihao Group, we offer forged flanges over a dozen different material grades. If you need a flange, give us a call or send an e-mail to begin your inquiry. Email:sales@haihaogroup.com