Selecting the right flange face finish to improve the sealing performance

The finish on the flange face requires a specific roughness to ensure that this surface be compatible with the gasket and provide a high quality seal, which is measured as an Arithmetical Average Roughness Height (AARH) and determined by the standard used.For example,in ANSI B16.5 and EN1092-1 specifies face (raised face and flat face) finishes within a rang 125 AARH-500 AARH (3.2 Ra to 12.5 Ra).

There are some kinds of flange face finish,like smooth finish,serrated finish and stock finish (sealing line).

Smooth Finish

This finish shows no visually apparent tool markings. These finishes are typically utilized for gaskets with metal facings.The smooth surfaces mate to create a seal and depend on the flatness of the opposing faces to effect a seal.

Smooth finish flanges are more common for low pressure or large diameter pipelines Smooth finish roughness is 125-250 AARH ( Ra 3.2 – 6.3), is used with solid metal and Spiral Wound Gaskets.

Serrated finish

Serrated finish have Spiral Serrated and Concentric Serrated.Spiral Serrated is a continuous or phonographic spiral.Concentric Serrated is comprised of concentric grooves.Used with soft gaskets or Non metallic flat gasket, such as NON Asbestos, PTFE gasket and flexible graphite composite gasket.

Stock finish (1-3 pieces of water sealing lines)

Stock finish is the most widely used.Practically,is suitable for all ordinary service conditions.Under compression,the soft gasket will embed into this finish.which helps create a seal, and a high level of friction is generated between the mating surfaces.

Stock finish roughness is 250-500 AARH (Ra 3.2-12.5).

May you have probably seen this request specification:

Serrated finishing 125 – 250 micro inches ( Ra = 3.2 – 6.3 micro meter = 125 – 250 AARH).

As said above,AARH stands for Arithmetic Average Roughness Height. It is used to measure the roughness (rather smoothness) of surfaces. 125 AARH means 125 micro inches.there is a Surface roughness Conversion chart

| Ra Micro-meters |

Ra Micro-inch (AARH) |

| 0.025 | 1 |

| 0.05 | 2 |

| 0.1 | 4 |

| 0.2 | 8 |

| 0.4 | 16 |

| 0.8 | 32 |

| 1.6 | 63 |

| 3.2 | 125 |

| 6.3 | 250 |

| 12.5 | 500 |

| 25.0 | 1000 |

| 50.0 | 2000 |

Have you ever encountered a leak in the flange joint due to poor sealing? One of reason may be flange face finish can’t match with gasket.If we use smooth finish for soft gaskets, enough “biting effect” will not occur and hence the joint may develop leak.Maybe only to change the suitable gasket,can solve the problem easily.

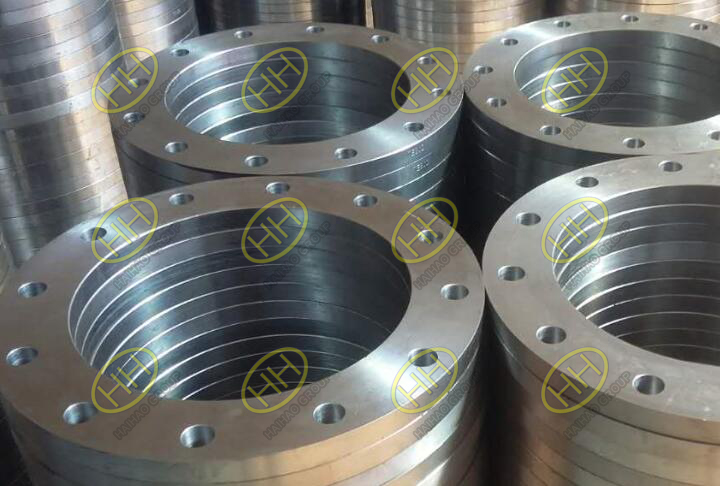

Hebei haihao group has more than 30 years of experience in flange and pipe fitting manufacturing,can provide customers with comprehensive advice and suggestions of the pipeline.