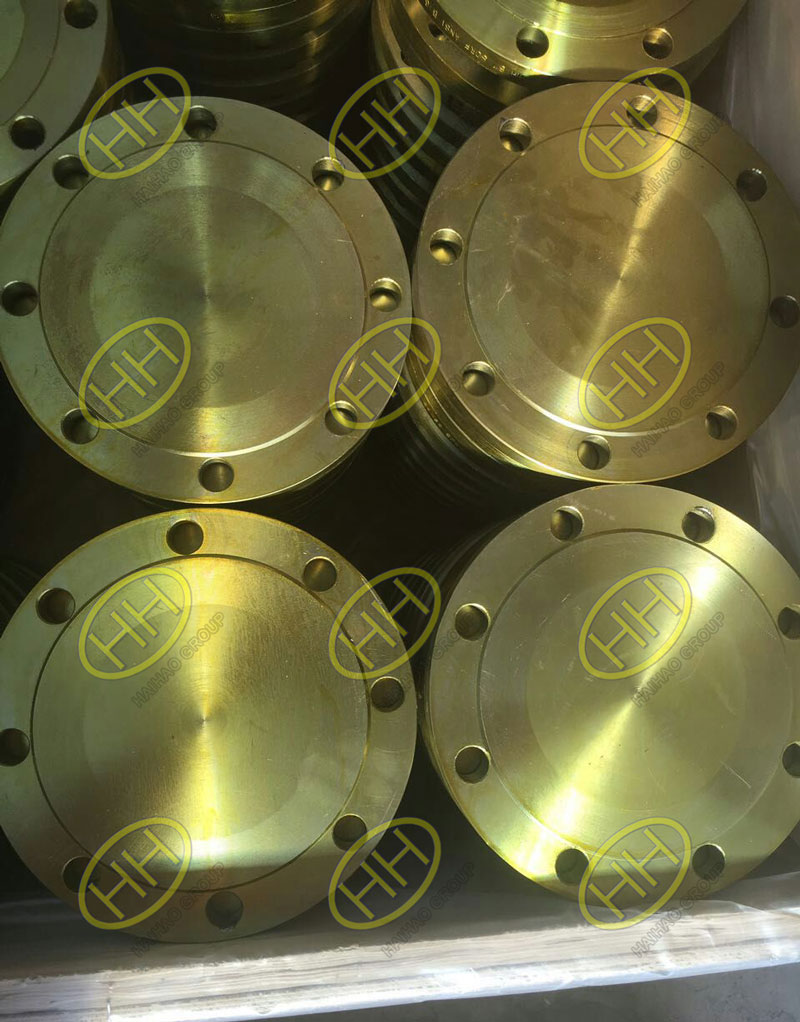

Introduction of blind flange

Blind flange(abbreviation is BL),its proper name is flange cover.It is a flange without holes in the middle for sealing the pipe plug.There are many types of sealing surface,such as flat face,raised face,ring joint face,tenon and groove surface,and ring connection surface.

Materials of blind flange:

Commonly the material of the blind flange should be same with the matched flange for joint.Since the blind flange is not welded with the pipes or vessel,some times the material could be different with the pipe material or the other flange in the joint.

Haihao Group can supply carbon steel blind flange,stainless steel blind flange and alloy steel blind flange.

Carbon steel:ASTM A105,A350 LF2,SS400,P235GH,P250GH,C22.8,Q235,20#,16Mn.

Stainless steel:ASTM A182 F304,F304L,F316,F316L,F321,F347,F310,F44,F51 etc.

Alloy steel:ASTM A694 F42,F46,F52,F56,F60,F65,F70,A182 F5,F9,F91,F12,F11,F22 etc.

Standards of blind flange:

Haihao Group supply blind flanges according to international standards such as ANSI/ASME B16.5,ANSI/ASME B16.47,AWWA C207,API 6A/6B/6BX,DIN 2527,EN 1092,BS 10,BS 4504,JIS B2220,GOST 12820,GOST 12821,SABS 1123,AS 1219 etc.

Production process:mainly divided into forging,casting,cutting and these three kinds.

The casting flange has accurate shape and size,small workload and low cost,but has casting defects (pore,crack, inclusion);the inner structure of the casting is poor streamlined (if it is a cutting part, the streamlined shape is worse);

Forged flange is generally lower in carbon content than cast flange,less easy to rust,better streamlined forging,compact structure and better mechanical properties than cast flange.

Improper forging process will also lead to large or uneven grains,hardening cracks and higher forging cost than casting flange.

Forgings can withstand higher shear and tensile forces than castings.

The advantages of castings are that they can produce more complex shapes and have lower cost.

The advantages of forgings are that the internal structure is uniform and there are no harmful defects such as blowhole and inclusion in the casting.

We also can supply other high pressure forged flanges products,such as weld neck flange,slip on flange,threaded flange,socket weld flange,plate flange,orifice flange,spectacle blind flange,lap joint flange etc.If you want to know more about our products,please email us:sales@haihaogroup.com