Manufacturing process of forged flanges-free forging

Forged flange is a flange in mechanical performance is one of the best products,its raw material is commonly tube billet,and then after cutting to constantly pounding,to eliminate the segregation of steel ingot defects,osteoporosis, etc.Price and mechanical properties are higher than normal casting flanges.The forging flange is mainly made of carbon steel,alloy steel,stainless steel.

Forging process generally consists of the following processes,namely,selecting high quality billet blanking,heating, forming and cooling after forging.The forging process includes free forging,die forging and membrane forging.In production,different forging methods are selected according to the quality of forgings and the quantity of batches produced.

Free forging has low productivity and large processing allowance,but its tools are simple and versatile,so it is widely used to forge forgings with simple shape and small batch production.Free forging equipment includes air hammer,steam-air hammer and hydraulic press,which are suitable for the production of small,medium and large forgings respectively.Die forging has high productivity,simple operation and easy to realize mechanization and automation.Die forgings have high dimensional accuracy,small machining allowance and more reasonable distribution of fiber structure,which can further improve the service life of parts.

The basic process of free forging: when forging freely,the shape of forgings is gradually forged by some basic deformation processes.The basic processes of free forging include upsetting,drawing,punching,bending and cutting.

The process are:

- Upsetting is the process of forging the billet along the axis to reduce its height and increase its cross section. This process is often used to forge gear blanks and other disc forgings. Upsetting can be divided into total upsetting and partial forging.

- Drawing and elongation is a forging process that increases the length of blank and decreases its cross-section. It is usually used to produce axle blanks, such as lathe spindle and connecting rod.

- Forging process of punching through hole or non-through hole on blank with punch.

- The forging process in which the billet is bent to a certain angle or shape by bending.

- The forging process in which part of the billet rotates at a certain angle relative to the other part by torsion.

- Forging process of cutting and cutting blank or cutting blank head.

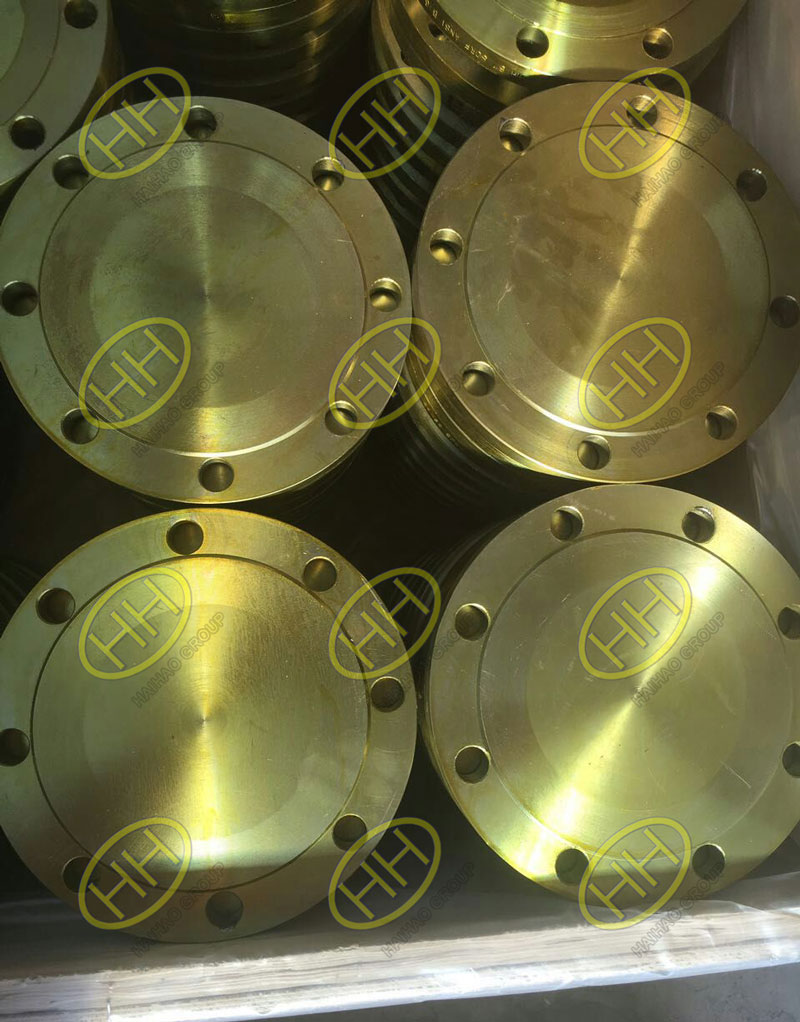

Haihao Group manufacture seamless and welded steel pipes,butt welding pipe fittings,forged pipe fittings and high pressure forged flanges products more than 30 years,we have advanced forging equipment and professional technician,and we can produce pipeline products as per clients requirement.If you have any questions,please email us:sales@haihaogroup.com