How Nickel Alloy Becomes the Core of Corrosion Resistance in Ultra-High Pressure Flanges

An In-Depth Look at High-Performance Flanges Made from UNS N06625

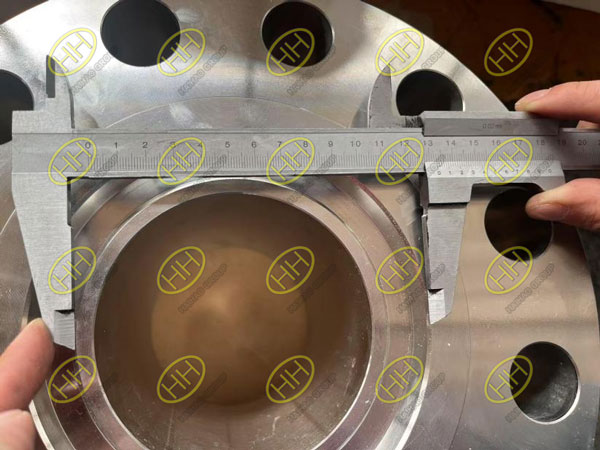

In offshore oil fields and high-sulfur (H₂S) wellhead environments, traditional carbon steel flanges often suffer premature failure due to severe corrosion. As a result, nickel-based alloy flanges, especially those made from ASTM B564 UNS N06625 (Inconel 625), have emerged as the material of choice for demanding high-pressure, corrosive applications. This article explores how nickel alloy flanges ensure safe, long-term operation in 10,000 PSI systems.

1.The “Genetic Code” of UNS N06625 Nickel Alloy

UNS N06625, commonly known as Inconel 625, is a solid-solution-strengthened nickel-based superalloy designed for exceptional resistance to corrosion and extreme environments.

Chemical Composition

With nickel content exceeding 58%, UNS N06625 is fortified by molybdenum (Mo) and niobium (Nb). These elements form a strong barrier against:

Chloride-induced pitting and crevice corrosion

Hydrogen sulfide (H₂S) stress corrosion cracking (SCC)

Mechanical Strength

Even under elevated temperatures, UNS N06625 retains outstanding mechanical properties, with:

Tensile strength ≥ 930 MPa (135,000 psi)

Excellent fatigue resistance and thermal stability

These characteristics make it ideal for high-pressure wellhead and subsea equipment subject to cyclic thermal and mechanical stress.

2.Dual Certification: NACE MR0175 + ASTM B564

When it comes to high-risk environments, material compliance is non-negotiable. The following certifications validate the quality and reliability of nickel alloy RTJ flanges:

NACE MR0175 / ISO 15156

This specification ensures the material can withstand sulfide stress cracking in sour service environments with H₂S concentrations, supporting safe operation for over 20 years.

ASTM B564

ASTM B564 outlines the forging standards for nickel alloy flanges, requiring:

Strict control of impurities such as sulfur and phosphorus (≤ 0.015%)

Prevention of intergranular corrosion through precise alloy processing

Together, these standards guarantee excellent corrosion resistance and structural integrity for API 6A 10000 PSI weld neck flanges.

The premium value of nickel alloy flanges is justified by their exceptional corrosion resistance, mechanical reliability, and compliance with the world’s most stringent industry standards. As seen in real applications, UNS N06625 RTJ flanges not only ensure safety and performance in ultra-high pressure systems, but also help oil and gas operators reduce long-term maintenance costs and extend asset lifespans in some of the most hostile environments on earth.

If you’re looking for a corrosion-resistant flange solution for offshore, subsea, or sour service applications, nickel alloy weld neck flanges from Haihao Group are engineered to deliver lasting value. Email:sales@haihaogroup.com