Flange gaskets:non-metallic gaskets,semi-metallic gaskets,metallic gaskets

The function of gaskets is to interpose a semi-plastic material between the flange facings,the material which, through deformation under load seals the minute surface irregularities to prevent leakage of the fluid.Gaskets can be generally divided into three main categories as follows:

Non-Metallic Gaskets:

Non-metallic gaskets are usually composite sheet materials are used with flat-face and raised-face flanges in low pressure class applications.Non-metallic gasket relates to a gasket material that is easily compressed under bolt load. These non-metallic gasket (know as soft gasket) material can be chosen from a large variety of elastomers,compressed non-asbestos,PTFE,flexible graphite and high temperature sheet products.Full-face gasket types are suitable for use with flat-face flanges.Flat-ring gasket types are suitable for use with raised face flanges.Non-metallic gaskets are used in a large range of applications such as pipe flanges,heat exchangers, compressors,and bonnet valves.

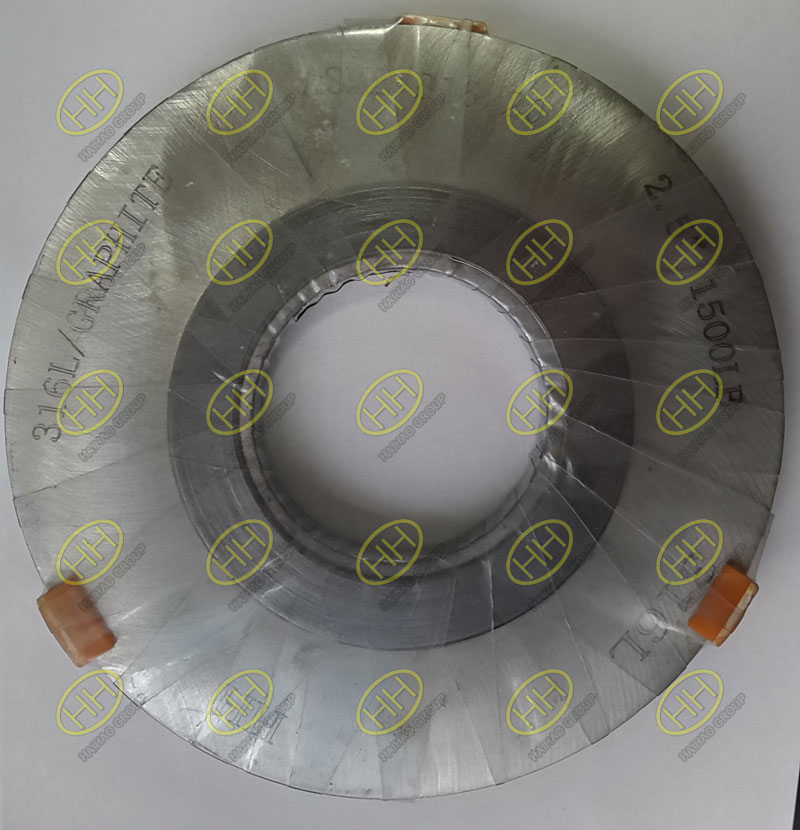

Semi-Metallic Gaskets:

Semi-metallic gaskets are composites of metal and non-metallic materials.The metal is intended to offer strength and resiliency,while the non-metallic portion provides conformability and sealability.Commonly used semi-metallic are spiral wound,metal jacketed,cam profile and a variety of metal-reinforced graphite gaskets.

Semi metallic gaskets are designed for the widest range of operating conditions of temperature and pressure. Semi-metallic are used on raised face,male-and-female and tongue-and –groove flanges.

Metallic Gaskets:

Metallic gaskets are fabricated from one or a combination of metals to the desired shape and size. Often used metallic gaskets are ring-type-joint gaskets (RTJ). They are always applied to special, accompanying flanges which ensure good,reliable sealing with the correct choice of profiles and material.It is suitable for high-pressure and temperature applications and require high bolt load to seal.

Ring Type Joint gaskets are designed to seal by “initial line contact” or wedging action between the mating flange and the gasket. By applying pressure on the seal interface through bolt force, the “softer” metal of the gasket flows into the microfine structure of the harder flange material, and creating a very tight and efficient seal.

Flange gaskets shall be selected based on multiple process factors,such as operating temperature/pressure,type of fluid conveyed by the pipeline,flange type,size,pressure rating,material grade,and specifications.

Dimensional Standards:

API 601– Metallic Gasket for Refinery Piping

BS 3381– Spiral Wound Gaskets to suit BS 1560 Flanges

ANSI B 16.20– Metallic Gasket for Steel Pipe Flanges, Ring Joint, Spiral Wound and Jacketed

ANSI B 16.21– Non-Metallic flat Gasket for Pipe Flanges

We supply all types flanges and gaskets in high quality,if you want to know more about our products,please feel free to contact us.Our email address is:sales@haihaogroup.com