An introduction to flanged connections – FF vs RF vs RTJ explained

Flanged connections are essential in piping systems that require secure, detachable joints. They allow for easier maintenance, inspection, and replacement of components. However, not all flanges are the same. In this article, we’ll explain the most common flange face types: Flat Face (FF), Raised Face (RF), and Ring Type Joint (RTJ).

1.What Are Flanged Connections?

A flanged connection consists of:

Two flanges

A gasket between the flanges

Bolts and nuts to hold them together

Proper selection of flange face type ensures adequate sealing performance under different pressures and service conditions.

2.Flat Face (FF) Flange

Description: The gasket surface is entirely flat and even with the flange face.

Common Use: Cast iron, fiberglass, or brittle materials

Advantages:

Simple and economical

Good for low-pressure, non-critical applications

Limitations:

Lower sealing performance compared to RF and RTJ

Not suitable for high-temperature or high-pressure systems

3.Raised Face (RF) Flange

Description: Has a small raised portion around the bore where the gasket sits.

Advantages:

Most common type in process piping

Allows better gasket compression

Works well with flat gaskets or spiral wound gaskets

Applications:

Oil and gas

Petrochemical

Steam and water systems

4.Ring Type Joint (RTJ) Flange

Description: Includes a precisely machined groove that holds a metal ring gasket.

Seal Mechanism: The ring is compressed into the groove to create a high-integrity seal

Advantages:

Excellent for high-pressure and high-temperature applications

Superior sealing in critical systems

Limitations:

More expensive

Requires accurate alignment and machining

Gaskets are non-reusable

5.How to Choose the Right Flange Face

Use FF flanges for:

Low-pressure, low-temperature services

Where both flange faces are cast materials

Choose RF flanges for:

General industrial applications

Systems with moderate pressure and temperature

Opt for RTJ flanges for:

High-pressure/high-temperature pipelines

Critical systems like oil refineries, offshore platforms

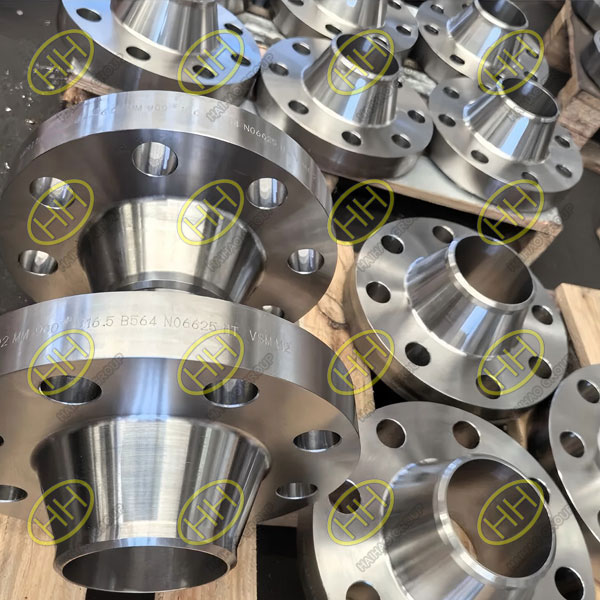

Haihao Group, a global leader in piping solutions, offers an extensive portfolio of sealing-surface flange products designed to meet your specific application requirements. For detailed specifications, technical support, or customized flange solutions, our expert team stands ready to assist. Contact us today to explore how we can deliver precision-engineered flange products tailored to your project needs. Email:sales@haihaogroup.com