- PRODUCT DETAIL

|

|||||||||||||||||||

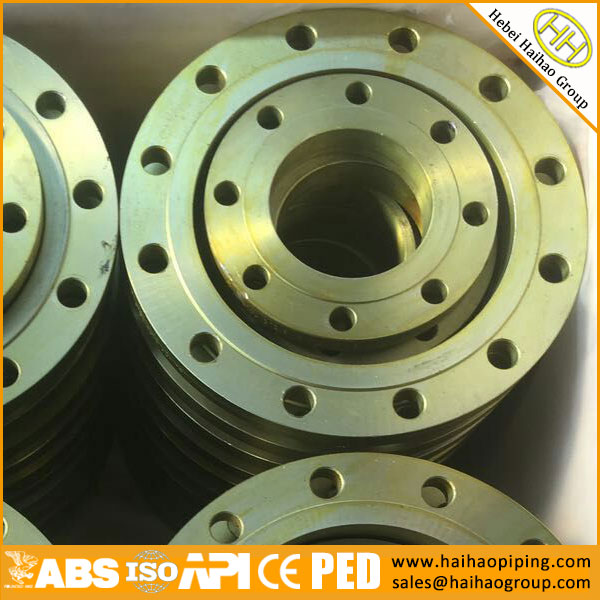

If you’re working on a high-pressure pipeline where welding isn’t ideal—or even allowed—threaded flanges offer a practical and safe solution. At Haihao Group, we manufacture and supply a full range of ANSI B16.5 forged threaded flanges, available in Class 300, 600, and 900, with Raised Face (RF) and Flat Face (FF) options.

What Are Threaded Flanges and When Should You Use Them?

Threaded flanges, also referred to as screwed flanges, are designed to connect pipes using internal threads instead of welding. They are commonly used in low-weld or no-weld situations, especially:

- In hazardous environments (gas, vapor, flammable liquids) where hot work is restricted

- For small-diameter piping, typically under 2″–4″

- In modular or temporary installations where reassembly is required

Threaded flanges eliminate the need for field welding and reduce the risk of heat-related distortion or safety hazards during installation.

Product Specifications

Standard: ANSI / ASME B16.5

Pressure Ratings: Class 300, 600, 900

Facing Options: Raised Face (RF), Flat Face (FF)

Thread Types: NPT (standard), BSPT optional

Sizes Available: ½” to 4″ (custom sizes available on request)

Materials:

- Carbon Steel: ASTM A105

- Stainless Steel: A182 F304 / F316

- Low-Temp: A350 LF2 (NACE MR0175 available)

- Alloy steel available for high-temperature systems

Quality Control & Testing

Every flange we produce undergoes strict inspection throughout the manufacturing process, including:

- Thread verification with calibrated gauges (NPT or BSPT)

- Dimensional checks per ASME B16.5

- Material identification (PMI testing if requested)

- Optional: Hydrostatic pressure testing on batch samples

- Surface treatments: black paint, anti-rust oil, or galvanized based on project needs

- Flanges are laser-marked with class, material, heat number, and size for full traceability

We can provide EN10204 3.1 Mill Test Certificates, NACE MR0175 compliance certificates, and other documents required for oil, gas, and offshore projects.

Installation & Application Scenarios

Threaded flanges are best suited for:

- Fire sprinkler systems (CL300)

- Compressed air lines

- Chemical distribution with strict hot-work policies

- Skid-mounted equipment requiring non-permanent connections

- Natural gas distribution where precision alignment is needed without welding

While threaded flanges are robust, we advise using them within the recommended pressure-temperature range. For high-vibration or extreme thermal cycling applications, a welded connection may be more appropriate.

Export Packaging & Global Shipping

At Haihao, every shipment is packed with international transit in mind:

- Flanges are individually separated with corrugated sheets

- Packed in fumigated plywood crates or steel-reinforced pallets

- Moisture protection film used for sea freight

- Outer packaging labeled with client PO, flange specs, and origin information

- Export documents include: CO, Form E, Packing List, Invoice, MTCs

We ship to over 80 countries and are experienced in documentation for Middle East, Southeast Asia, Europe, and North America.

Frequently Asked Questions (FAQ)

Q1: Can you supply Class 600 threaded flanges in stainless steel?

Yes. We stock A182 F304 and F316 threaded flanges in Class 300/600. Other grades (e.g., Duplex) are available on request.

Q2: What thread standards do you support?

NPT is the default per ASME B1.20.1. BSPT, PT, or custom threads can be produced with a drawing or spec.

Q3: Are these flanges suitable for sour service (H₂S)?

Yes, we offer threaded flanges in NACE MR0175-compliant materials, including A350 LF2 and stainless steels with confirmed chemistry.

Q4: What’s the maximum pressure you recommend for threaded flanges?

We supply up to Class 900, but threaded flanges should not be used in high-cycling, high-vibration systems under extreme temperatures.

Why Choose Haihao Group?

With over 40 years in pipeline flange manufacturing, we offer:

- Full in-house forging and machining capabilities

- Quick turnaround on small and large quantity orders

- Strict QC with traceable MTRs and international certifications

- Flexibility for non-standard threads and materials

If you’re looking for reliable ANSI B16.5 threaded flanges, delivered with documentation, quality control, and global shipment support—Haihao is ready to supply.