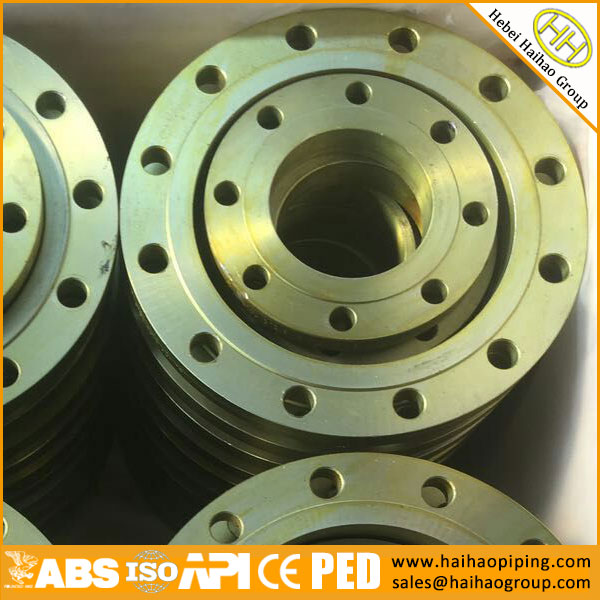

When you’re specifying flanges for piping systems, material traceability and precise machining are essential. At Haihao Group, we manufacture and supply ANSI B16.5 Class 150 plate flanges with raised face surfaces, produced to meet demanding industrial standards.

Unlike slip-on or weld neck flanges, plate flanges are a simple and cost-effective connection method. They are typically used in low- and medium-pressure applications where space or budget constraints make them preferable.

Product Overview

Standard: ANSI/ASME B16.5

Type: Plate flange, raised face

Class: 150#

Materials Available:

- Carbon steel ASTM A105

- Stainless steel grades 304/316

- Other alloys upon request

Size Range:

- 1/2″ to 24″ nominal pipe size

- Custom drilling patterns available

Each flange is precision-machined to ensure flatness, correct bolt hole alignment, and consistent sealing surfaces. The raised face helps improve gasket compression and achieve a leak-tight connection.

| Flange Type | Welding Method | Typical Application |

|---|---|---|

| Plate Flange | No welding neck | Low-pressure piping |

| Slip-On Flange | Fillet weld | Medium pressure systems |

| Weld Neck Flange | Butt weld | High-pressure, critical service |

Key Features and Benefits

- Forged from fully traceable billets for strength and durability

- Machined surfaces with roughness ≤ Ra3.2 to meet ASME sealing requirements

- Bolt holes and edges chamfered for safe handling and easier installation

- Marked with heat number, material grade, size, and pressure class for identification

- Optional coatings: black paint, anti-rust oil, or galvanizing

Whether you’re building a new line or replacing damaged components, our CL150 plate flanges offer a reliable sealing solution at competitive pricing.

Applications

These flanges are commonly used in:

- Process piping

- Water supply and fire protection systems

- HVAC pipelines

- Low-pressure steam distribution

- Equipment nozzles and temporary connections

Quality and Inspection

From my experience overseeing production, I know no two projects are alike. That’s why every batch undergoes strict inspection, including:

- Dimensional verification (OD, bolt circle, raised face height)

- Visual checks (no cracks, pitting, or machining defects)

- PMI testing when specified

- Flatness and thickness measurement

Inspection certificates and full traceability records are supplied with each order.

Packing and Delivery

We protect every flange before shipment:

- Each piece receives a protective coating or plastic film

- Bolt holes are covered as needed

- Flanges are stacked in fumigated wooden crates, separated by plywood to avoid scratches

- Heat numbers are clearly marked

Our team can arrange air or sea freight depending on project deadlines.

Why Choose Haihao Group?

Many clients share the same concerns:

- “Will the sealing face be smooth enough?”

- “How can we be sure the material matches specifications?”

- “Are the bolt holes precisely drilled?”

We address these questions by providing:

- Certified forging processes

- Third-party inspections if required

- Experienced technicians supervising every production stage

- Reliable documentation

This is how we’ve earned long-term partnerships in Europe, Southeast Asia, and the Middle East.

Frequently Asked Questions

Q: What’s the difference between a plate flange and a slip-on flange?

A: A plate flange is a flat disc welded directly to the pipe end, while a slip-on flange slips over the pipe and is fillet-welded inside and outside. Plate flanges are simpler but suited mainly for lower-pressure systems.

Q: Can you provide 3.1 material certificates?

A: Yes, we supply EN10204 3.1 MTCs including chemical composition and mechanical properties.

Q: Are protective coatings included?

A: All flanges are coated with rust-preventive oil or black paint. Galvanizing is available on request.

Q: What surface finish can I expect?

A: Standard finish is Ra3.2 or smoother on raised faces to ensure gasket performance.

Request a Quote

If you need ANSI B16.5 Class 150 plate raised face flanges, our engineers are ready to help you specify the right size and material.

📧 Email: sales@haihaoflange.com