Sealing principle of pressure vessel flange

Pressure vessel flanges are common and basic components that connect various parts of pressure vessel. They are widely used in petrochemical, electric power, atomic power, and other industries. For vessels, the function of flanges, gaskets, connecting bolts, studs, screws is to combine different pressure components while ensuring that the joint does not leak. The main failure form of the flange connection is leakage caused by stiffness failure. The medium inside the pressure vessel has toxic, flammable and explosive, high pressure and temperature characteristics. Once the pressure vessel leaks, a serious secondary disaster will occur, which threatens the safety of the body of pressure vessel, the surrounding equipment and people. So the priority in the design and selection is the overall sealing performance.

China’s standards for pressure vessel flanges can be dated back to the 1970s, when the ministries of machinery, petroleum and chemical industry issued the JB1157~1164-1973 standard. After a long-term trial and continuous revision, the latest standard is JB/T4700~4707-2000.

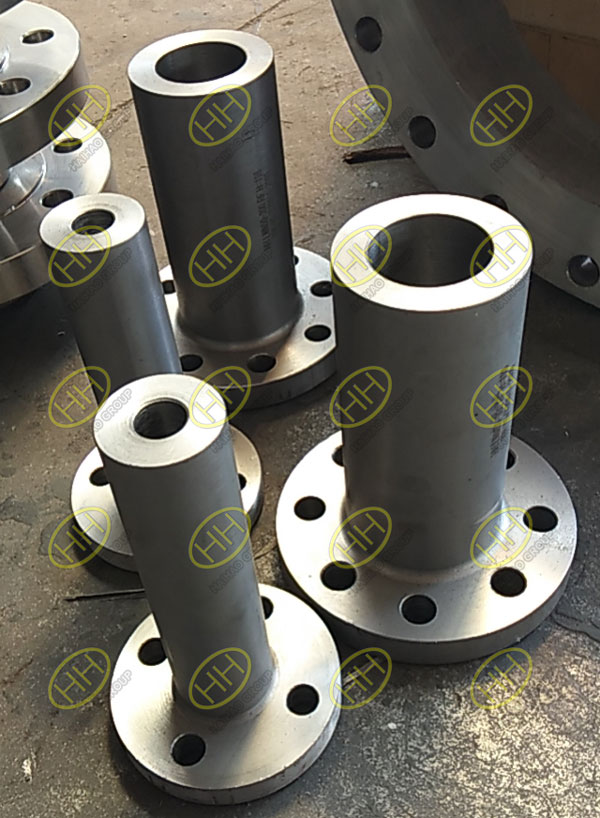

In terms of the structural form and working principle of flanges, there is not much difference between the pressure vessel flanges and the pipe flange except that the specification of flanges for pressure vessel is larger, and the pipe flanges are often directly connected to pipes or the inlet and outlet pipes of pumps, valves, etc.

The working principle of the pressure vessel flanges is that when their screws are preloaded, the force compresses the gasket till a certain degree that it is deformed through the flange ring. The sealing surface of flange and the uneven surface of the gasket will fill due to the deformation of gasket, which creates an initial sealing condition for preventing the leakage of fluid medium. At this time, the pressing force on the effective sealing area of the gasket is referred to as the initial sealing pressure. When the equipment or pipeline is subjected to the pressure of medium, the screw is stretched by the tensile stress, and the sealing surface of flange moves in the mutual separation direction, the pressing force between the sealing surface and the gasket, as well as the compression amount of gasket decrease, and the preloaded sealing pressure drops. If the gasket has sufficient resilience at this time, the deformation of the gasket can compensate the separation value of the screw and the sealing surface, and the preloaded sealing pressure is not less than the working sealing pressure, so the sealing condition of flange will remain. Conversely, if the resilience of the gasket is insufficient, the sealing pressure drops below the working sealing pressure, then the sealing ability loses.

Factors that affect the sealing of pressure vessel flanges are as follows:

The pretightening force of screws

The sealing performance of gaskets

The features of flange sealing surface

The rigidity of flanges

Operation conditions