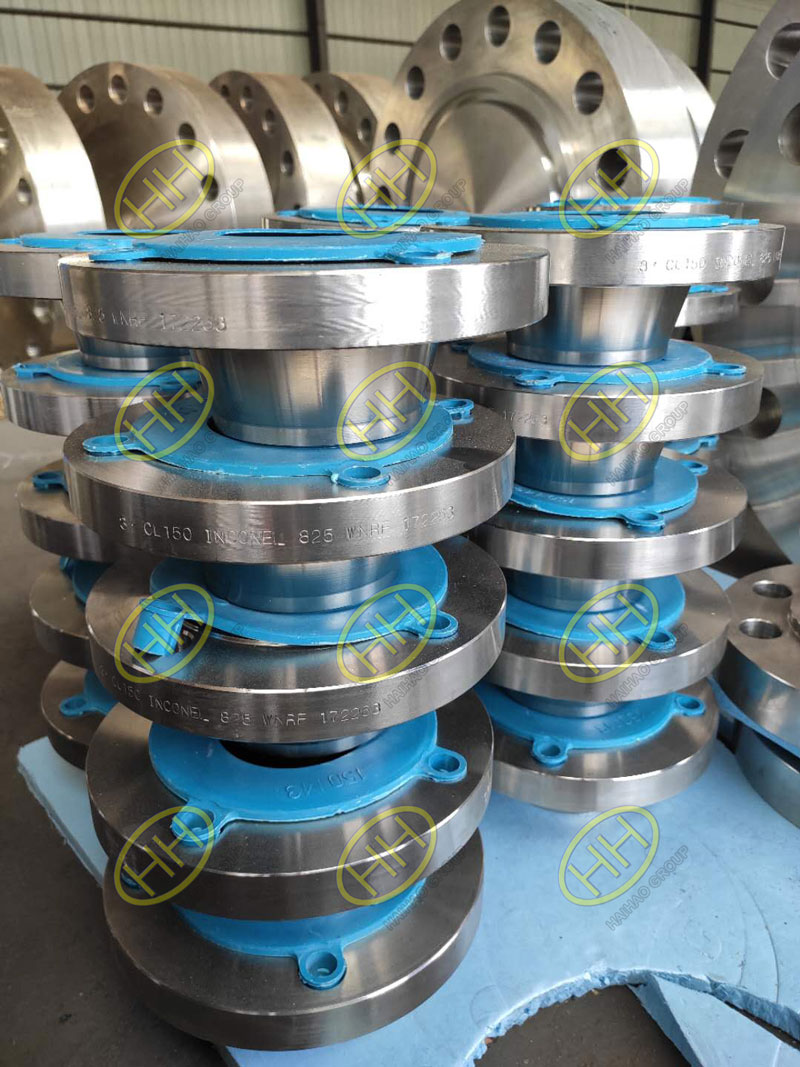

Knowing these points, you can have high quality weld neck flange

How can we have a high quality butt-welded flange with neck,which is what many of us want to know.Let us explain the following points for you, so that you have a high quality butt welding flange with neck.

1: The processing size of the butt-welded flange with neck, the material and specifications of the gasket should meet the standards or design requirements, the cushioning material has good elasticity, and it should also be resistant to corrosion.

2: Before assembling the butt-welded flange with neck, remove impurities (iron shavings, oil, etc.) from the surface and sealing surface until the metal luster is exposed. The sealing line on the flange sealing surface must also be clear.

3: Bolts and nuts cooperate well. Both threads must be complete and free of defects. The bolts used are of the same specifications, the installation direction is the same, and they should be evenly tightened symmetrically and crosswise. After tightening, the bolt should be exposed within 5mm of the nut, not more than 2 times the pitch.

4: When weld neck flange are butt-jointed, the sealing surfaces should remain parallel. The parallelism of the flange sealing surface allows deviation, that is, the maximum deviation of two symmetrical points in the diameter direction.

5: The neck butt welding flange connection should be parallel. The parallel deviation should not exceed 1.5mm and not more than 2mm.

6: For ease of disassembly, the distance between the flange surface, the fastening bolts and the building and the bracket should not be less than 200mm.

7: When assembling flanges and cylinders with neck butt welds, the flange squareness should be used to check the flange verticality.

8: Before using the butt-welded flange with neck to assemble the cylinder, be sure to use a ruler to check the end surface of the cylinder to ensure that the end face’s inclined size is not greater than 15 mm.

9: When the flange and the flange are connected, the sealing surfaces should be as parallel as possible.

10: Increasing the wall thickness of the wall (or pipe wall) at the connection with the flange will not only reduce the bending stress imposed on the wall by the flange, but the thickened wall will in turn increase the rigidity of the flange. Reduce bending stress in flanges.

11: Sealing gasket is the foundation of the entire flange connection (including flange, gasket, stud, nut). The material, structure and size of the gasket are one of the main factors affecting the bolt force and the flange moment.

12: Under the condition of constant bolt force, the smaller the distance between the center circle of the flange screw hole and the middle diameter of the gasket, the smaller the external force moment of the flange. When determining the diameter and number of bolts, the diameter of the center circle of the screw hole should be as small as possible.

The above are the points we should pay attention to. According to the above methods, you can have high quality weld neck flange. We are a professional flange manufacturer, producing high-quality flanges, which are exported to Europe, America, Southeast Asia, and other regions, won the trust of customers. If you need flanges, please contact us.Email:sales@haihaogroup.com