-

Haihao Group Exports EN 1092-1 ASTM A516 GR70 Flanges to Vietnam

Haihao Group has proudly completed another international delivery – a batch of EN 1092-1 flanges supplied to a long-term partner in Vietnam. The order consists of Type 01 B1 plate flanges and Type 05 B1 blind flanges, all produced in accordance with EN 1092-1 and ASTM A516 Grade 70 standar ...

-

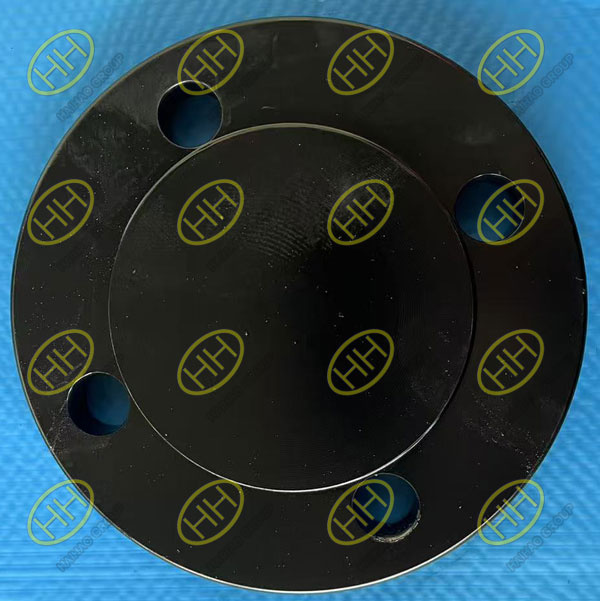

Haihao Group Supplies 24″ Paddle Blank Flange to Singapore Client

Haihao Group is pleased to announce the successful delivery of a 24-inch Paddle Blank Flange to one of our valued clients in Singapore. Manufactured according to ASME B16.48 Class 600 RF, this product is made from ASTM A240 316 stainless steel, ensuring excellent durability, corrosion resistance ...

-

Haihao Group Supplies Super Duplex Stainless Steel WN Flange RTJ to Singapore

Haihao Group has successfully delivered a batch of weld neck (WN) flanges with RTJ facing to a valued customer in Singapore. The product details are as follows: Product: WN Flange RTJ Size: 1″ Rating: 2500# Schedule: S-80S Standard: ASME B16.5 Material: ASTM A182 F55 (Super Duplex Stainle ...

-

Haihao Group Supplies Pipeline Products Including WN Flanges, Bolts, and Spiral Wound Gaskets

Haihao Group has successfully completed the shipment of a full set of pipeline products for a valued customer. The delivery included weld neck flanges, bolt sets, and spiral wound gaskets, ensuring a complete piping connection solution that meets international standards. GOST 33259 WN flange DN4 ...

-

Haihao Group Supplies High-Pressure ASME B16.5 A694-F65 WN RTJ Flanges to Singapore

Haihao Group has recently completed the supply of ASME B16.5 A694-F65 WN RTJ flanges to a key customer in Singapore. The shipment included: 2-inch weld neck RTJ flange, pressure class 2500#, SCH XXS wall thickness, with black paint finish. 8-inch weld neck RTJ flange, pressure class 1500#, SCH ...

-

Haihao Group Supplies EN1092-1 Plate Flanges and Blind Flanges to Vietnam

Haihao Group recently completed the supply of a wide range of EN1092-1 standard flanges for a valued client in Vietnam. The shipment included both TYPE01 B1 plate flanges and TYPE05 B1 blind flanges, manufactured in ASTM A516 GR70 carbon steel and designed to withstand demanding operating enviro ...

-

Haihao Group Delivers Spectacle Blind Flanges for Singapore Project

Haihao Group is proud to announce the successful shipment of a large batch of spectacle blind flanges to a key customer in Singapore. The order covered a wide range of materials, sizes, and pressure ratings, designed to meet the most demanding industrial environments, including offshore, petroch ...

-

Haihao Group Supplies High-Pressure RTJ Flanges for International Client

Haihao Group has successfully completed the delivery of high-pressure RTJ flanges for an international client. This order highlights our strong capability in producing weld neck flanges (WN flanges) and blind flanges that meet stringent project specifications, international standards, and NACE r ...

-

Haihao Group Supplies High-Quality Flanges to UAE Client

Haihao Group is proud to announce the successful delivery of a batch of flanges to a valued client in the United Arab Emirates (UAE). This shipment demonstrates our strong manufacturing capability in supplying weld neck flanges (WN), blind flanges (RF), and socket weld flanges in various materia ...

-

Haihao Group supplies ASME B16.5 flanges to Singapore client

Haihao Group is proud to announce the successful shipment of a batch of ASME B16.5 flanges to a valued customer in Singapore. This order includes a wide range of forged steel flanges manufactured from A105N and A350 LF2 Class 1 materials, ensuring reliable performance in high-pressure piping sys ...

-

Haihao Group Ships A105 RF 150# Slip On Flanges to Brazil

Haihao Group is pleased to announce the successful shipment of a new batch of A105 RF 150# slip on (SO) flanges to a valued customer in Brazil. This order included flanges in multiple dimensions ranging from 2″, 3″, 4″, 6″, 8″, 10″, 12″ to 14″, man ...

-

Haihao Group Supplies A105N RF Weld Neck Flanges to Singapore

Haihao Group has recently completed the supply of RF Weld Neck (WN) flanges for a valued customer in Singapore. The order included high-quality A105N forged carbon steel flanges, produced in full compliance with ASME B16.5 standards. Product Details WN Flange RF, 14″, 150#, STD, Material: ...