Haihao Group Delivers Incoloy 800H Weld Neck Flanges to the UAE

Haihao Group recently completed the delivery of for an industrial piping project in the United Arab Emirates.

The flanges were produced in strict accordance with ASME B16.5 dimensional requirements and ASTM B564 material specifications, meeting NACE service conditions for demanding operating environments.

Supplied Flange Specifications

The shipment included the following WN RF flanges:

- 2″ Weld Neck Flange

Pressure class: Class 150

Pipe schedule: SCH 80

Facing: RF (Raised Face)

Material: Incoloy 800H

Standard: ASME B16.5 / ASTM B564 (UNS N08810)

Service: NACE compliant - 3/4″ Weld Neck Flange

Pressure class: Class 150

Pipe schedule: SCH 80

Facing: RF (Raised Face)

Material: Incoloy 800H

Standard: ASME B16.5 / ASTM B564 (UNS N08810)

Service: NACE compliant

All flanges were supplied with full material traceability and inspection documentation.

Why Incoloy 800H for Weld Neck Flanges

Incoloy 800H (UNS N08810) is widely used in high-temperature and high-stress applications due to its stable microstructure and excellent mechanical strength.

Key material advantages include:

- Outstanding resistance to oxidation and carburization

- Good creep and rupture strength at elevated temperatures

- Excellent performance in petrochemical and energy applications

- Proven suitability for NACE-related service conditions

When combined with a weld neck design, these properties ensure superior load distribution, reduced stress concentration, and long-term reliability in critical piping systems.

Typical Applications

Incoloy 800H WN flanges are commonly used in:

- Oil and gas processing facilities

- Petrochemical and refinery piping systems

- High-temperature process units

- Power generation and heat transfer equipment

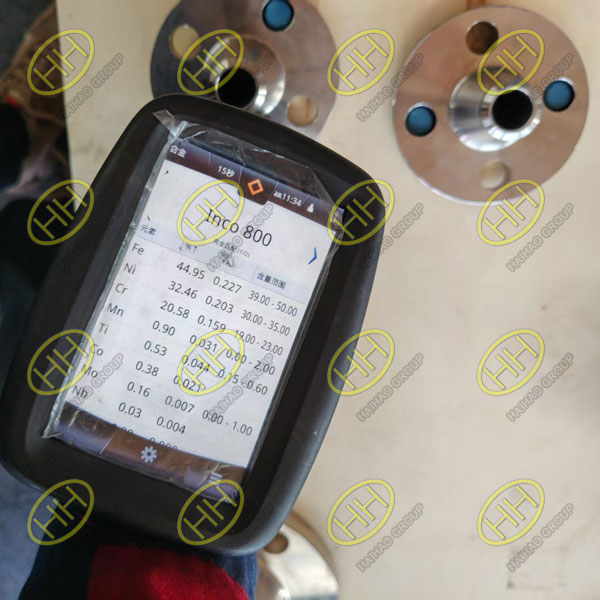

Quality Control and Inspection

Haihao Group applies strict quality assurance procedures for all nickel alloy flanges, including:

- Chemical composition analysis

- Mechanical property verification

- Dimensional inspection to ASME B16.5

- Surface finish and facing inspection

- Complete traceability with EN 10204 3.1 certification

Haihao Group – Your Reliable Nickel Alloy Flange Supplier

With extensive experience supplying nickel alloy flanges to Middle East projects, Haihao Group provides customized solutions for demanding applications.

Our product range covers Incoloy, Inconel, Monel, Duplex, and Super Duplex flanges, manufactured to international standards and customer-specific requirements.