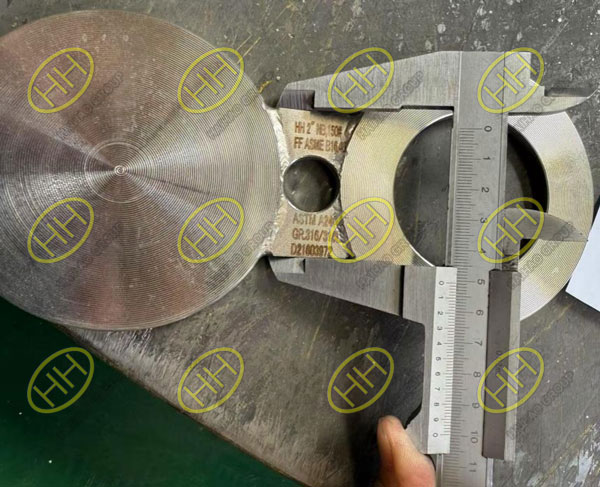

Precision stainless steel spectacle blinds manufactured to ASME B16.48 standard

In 2025, Haihao Group successfully completed the production and quality inspection of stainless steel spectacle blinds for a valued client in Singapore. These critical flow-control components were manufactured from ASTM A240 Grade 316/316L stainless steel and in full compliance with the ASME B16.48 standard. Each unit was supplied with full material traceability and EN 10204-3.1 certification.

Product Details Supplied:

1 ½” NB Spectacle Blind

Material: ASTM A240 Gr. 316/316L

Seal face:Flat Face (FF)

Standard: ASME B16.48

Certification: EN 10204-3.1

2″ NB Spectacle Blind

Material: ASTM A240 Gr. 316/316L

Seal face:Flat Face

Standard: ASME B16.48

Certification: EN 10204-3.1

What is a spectacle blind flange?

A spectacle blind flange is a mechanical safety device used to isolate a section of pipeline or equipment. It consists of a solid disk (blind) and a ring (spacer) joined together like a pair of spectacles. By rotating the assembly, operators can either block (blind) or allow flow (open) in the pipeline.

What are the applications of spectacle blind flange?

Pipeline isolation during maintenance

Safety control in chemical, petrochemical, and offshore industries

Shut-off for pressure vessel inspection

Why ASTM A240 316/316L is ideal for spectacle blinds?

ASTM A240 Grade 316/316L stainless steel offers a balance of corrosion resistance, mechanical strength, and weldability. It is the preferred choice for spectacle blinds used in environments exposed to chlorides, acids, or high humidity.

Key Benefits of 316/316L:

Excellent resistance to pitting and crevice corrosion in chloride-rich media

Low carbon content in 316L reduces risk of carbide precipitation during welding

Good performance in high-temperature and high-pressure conditions

Superior durability in offshore, marine, and refinery applications

What Does ASME B16.48 Mean?

ASME B16.48 is the global design standard for line blanks, including spectacle blinds and spacers. Products manufactured to this standard ensure:

Dimensional accuracy and compatibility with ASME B16.5 flanges

Standardized thickness and bore alignment for safe sealing

Pressure class compliance – these spectacle blinds are rated for 150# flanges

Interchangeability in critical piping systems

Haihao Group ensures strict compliance with ASME B16.48 during manufacturing, using CNC machining and precision cutting processes.

Certified Quality: EN 10204-3.1

Every spectacle blind was supplied with an EN 10204-3.1 inspection certificate, which includes:

- Full chemical composition

- Mechanical test results

- Heat number traceability

- Visual and dimensional inspection records

This guarantees the product’s conformance to both customer specifications and international standards.

Practical Use Cases

Haihao Group’s spectacle blinds made from ASTM A240 316/316L are widely used in:

- Offshore oil and gas piping systems

- Refineries and petrochemical plants

- Power generation systems

- Pulp and paper mills

- Chemical processing facilities

Their corrosion resistance, mechanical integrity, and ease of switching between open and closed positions make them indispensable in safety-focused applications.

Conclusion: A Reliable Flow Control Solution

When it comes to safety and system integrity, spectacle blind flanges made from ASTM A240 316/316L stainless steel offer unmatched reliability. Complying with ASME B16.48, they ensure proper flow isolation for both maintenance and emergency scenarios.

Haihao Group takes pride in delivering high-performance flow control components to global clients with full documentation and compliance. Whether you need spectacle blinds, line blinds, or other forged fittings, our factory ensures precision, quality, and timely delivery.

Contact us today to request a quote or learn more about our stainless steel flange and fitting solutions. Email:sales@haihaogroup.com