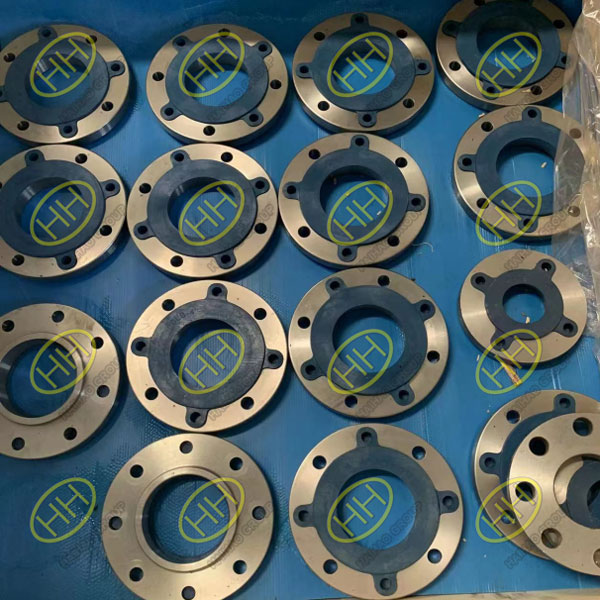

Premium ASME B16.5 RF CL300 ASTM A105N weld neck flanges

We are delighted to introduce our top-of-the-line product, the ASME B16.5 WN Flange RF CL300 ASTM A105N, which has been exclusively designed to meet the demanding requirements of shipyards. Our ASME B16.5 RF CL300 ASTM A105N weld neck flanges are designed to provide exceptional strength, durability, and efficiency.

ASME B16.5 RF CL300 ASTM A105N Weld Neck Flanges are widely used across diverse industries and applications, including:

- Oil and Gas: Exploration, production, refining, and transportation of hydrocarbons, where high pressure and temperature conditions prevail.

- Petrochemical: Chemical processing plants, refineries, and petrochemical complexes requiring robust and reliable piping solutions.

- Power Generation: Thermal power plants, nuclear facilities, and renewable energy projects needing durable and efficient flange connections.

- Water Treatment: Municipal and industrial water treatment plants requiring corrosion-resistant and high-performance flanges for fluid conveyance.

- General Industry: Manufacturing, construction, and infrastructure projects demanding high-quality flanges for various piping systems.

Features and Benefits:

Superior Rust Protection: Understanding the harsh marine environment, we have taken extra measures to meet your requirements. Our ASME B16.5 WN Flange RF CL300 ASTM A105N is meticulously coated with a rust-preventing oil, ensuring its resilience against corrosion and extending its service life.

Damage Prevention with Gasket Separation: To safeguard the integrity of the flange, we provide high-quality gaskets that effectively separate flange-to-flange connections. This protective measure prevents any potential damage during transit, ensuring that the flanges arrive at your destination in perfect condition.

Impeccable Surface Finish: Our flanges exhibit a flawless, mirror-like surface finish, free from any tool marks or damage. The impeccable appearance not only enhances the aesthetics of your installation but also reflects our commitment to delivering products of the highest quality.

Secure Packaging: We understand the importance of protecting your valuable investment during transportation. With utmost care, each flange is meticulously packaged using wrapping film to provide an additional layer of protection. Furthermore, we offer the option of packaging the flanges on pallets or in wooden crates, ensuring their safe arrival at your shipyard.

Thermal Insulation: To meet your specific requirements, we provide thermal insulation pads to separate the flanges during storage and transportation. This precautionary measure prevents heat transfer between the flanges, ensuring their integrity and avoiding any potential thermal damage.

Protective Cap for Each Flange: We go the extra mile by providing a protective cap for each flange, safeguarding the critical sealing surfaces from any potential damage. This attention to detail ensures that the flanges are ready for immediate installation, eliminating the need for additional cleaning or reconditioning.

The ASME B16.5 WN Flange RF CL300 ASTM A105N is the perfect choice for shipyard applications, thanks to its exceptional quality, meticulous attention to detail, and compliance with your specific requirements. With rust protection, gasket separation, flawless surface finish, secure packaging, thermal insulation, and individual protective caps, our flanges are ready to meet your needs. Trust our commitment to delivering superior products that excel in performance, durability, and reliability. Experience seamless installations and enjoy the peace of mind that comes with using our top-of-the-line flanges in pump rooms and cargo oil pipe installations.